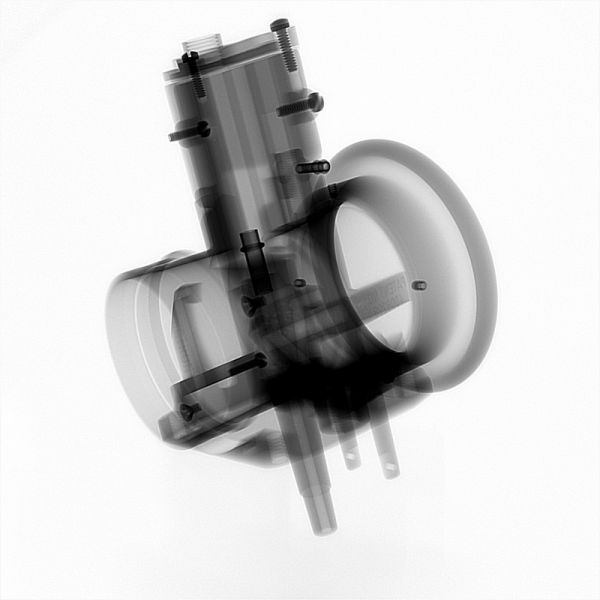

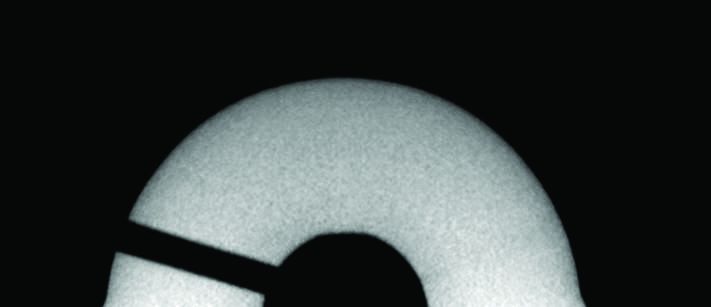

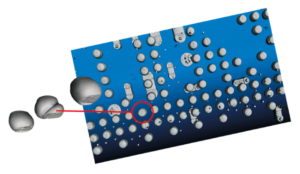

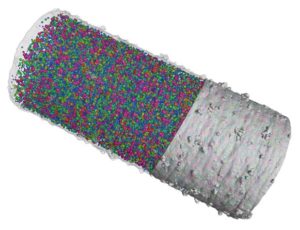

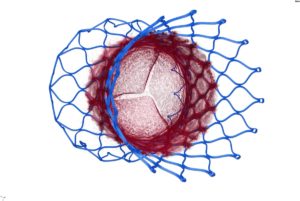

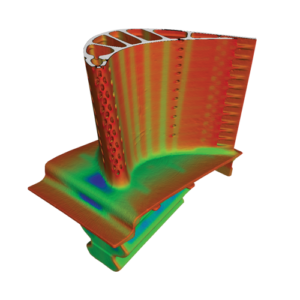

Lighter alloys and lower engineering safety margins have driven the product quality standards to higher levels than ever before. Computed tomography (CT) and digital x-ray imaging have become invaluable tools in this effort by providing manufacturers with the ability to engineer products of higher quality with tighter tolerances, while also providing them a way to inspect the products when production begins.

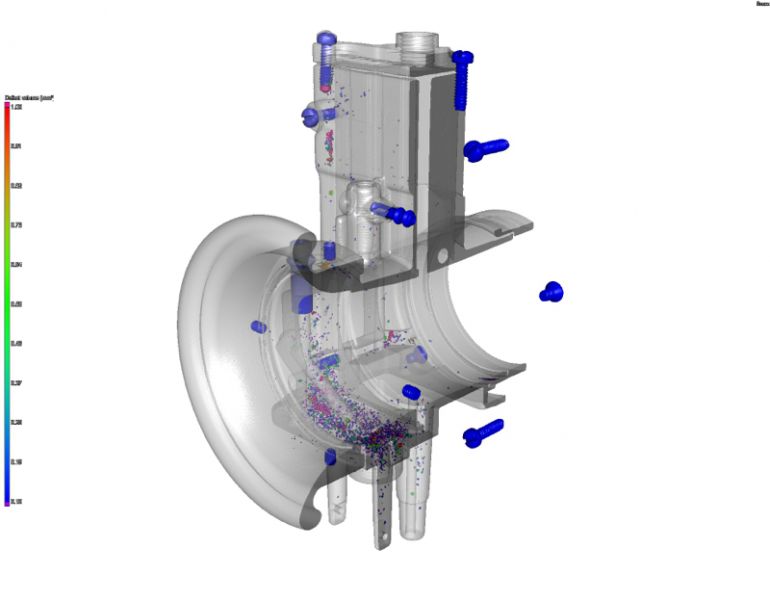

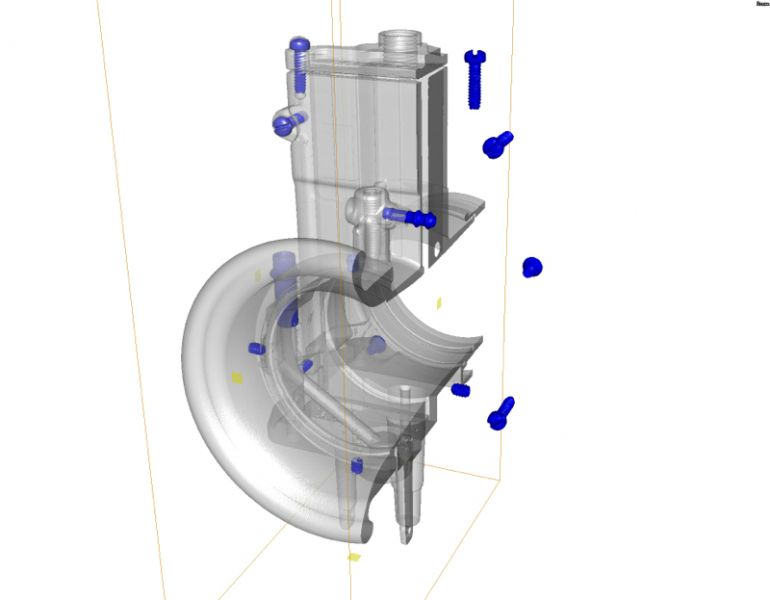

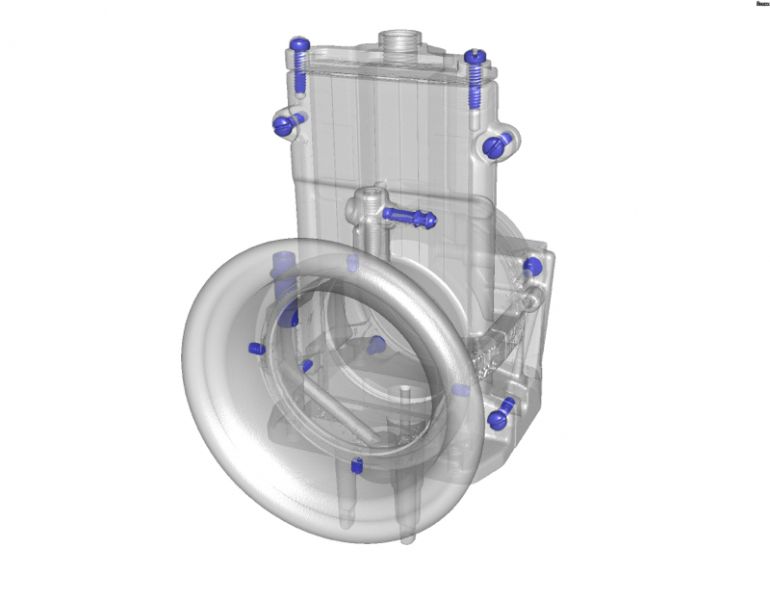

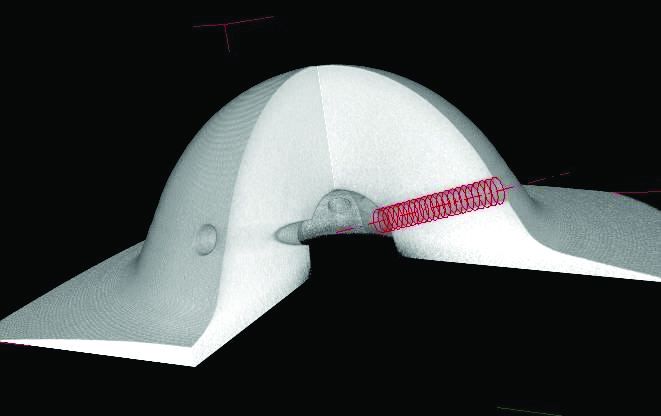

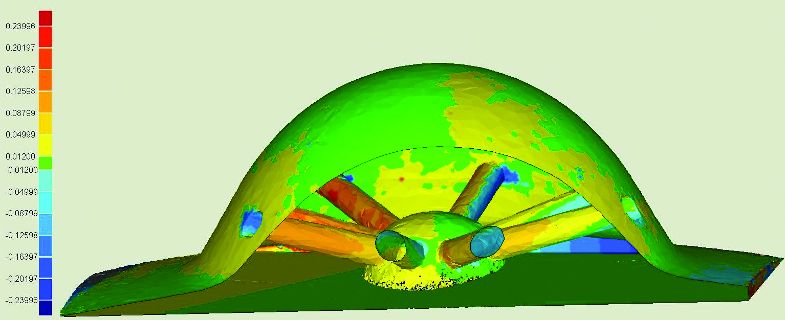

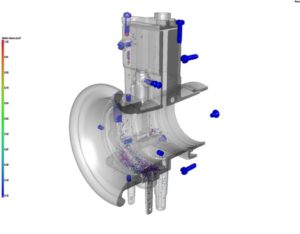

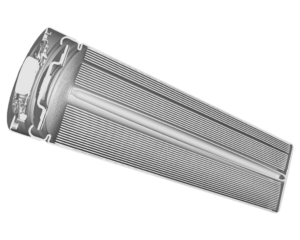

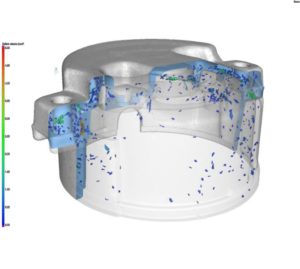

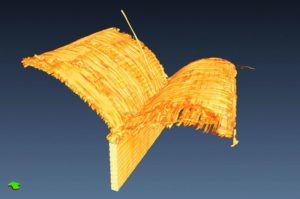

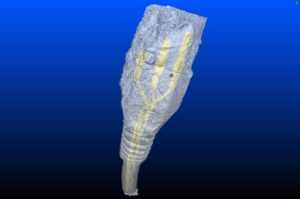

CT is often used during the qualification process to acquire dimensional information on all internal and external features for a comparison to the original CAD model. It is also very valuable during the process development phase in assisting casting engineers with evaluating the effects of changes to the casting molds and processes.

- Common uses: product screening, metrology, quality control, porosity analysis, process development.

- Common products: castings, plastics, cast wheels, engine components, tires, airbags, fuel injectors, brake components.