The XT H Series covers a wide range of applications

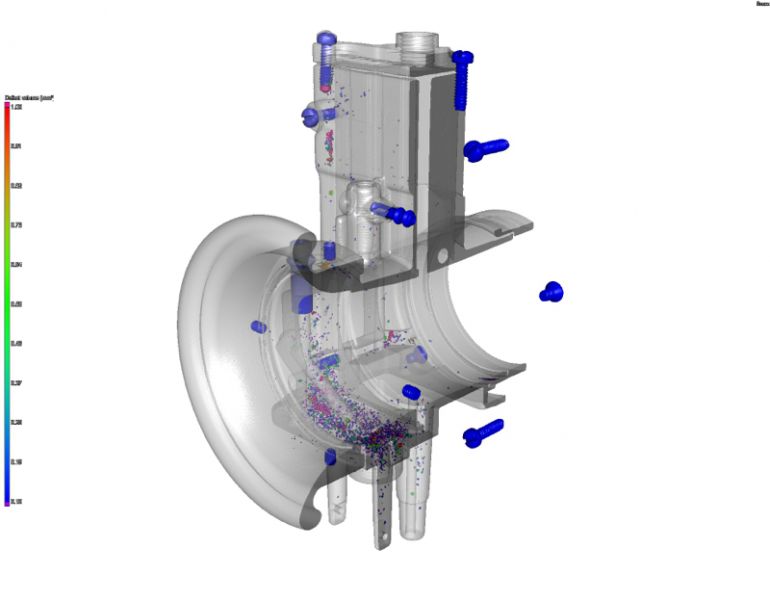

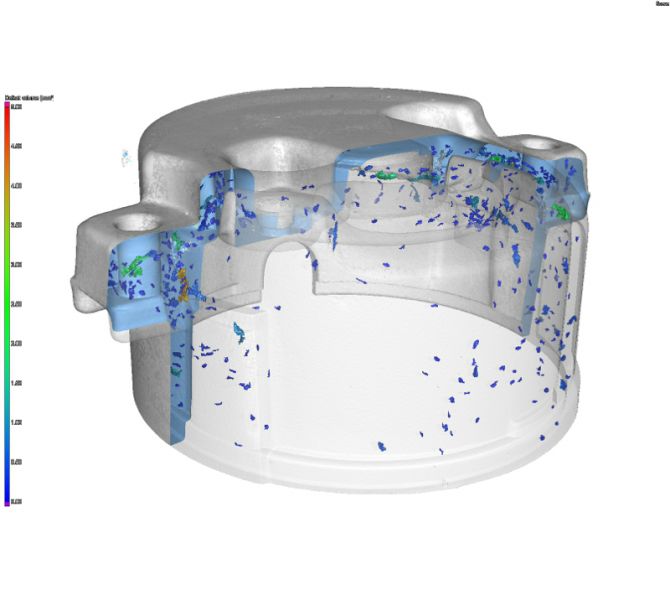

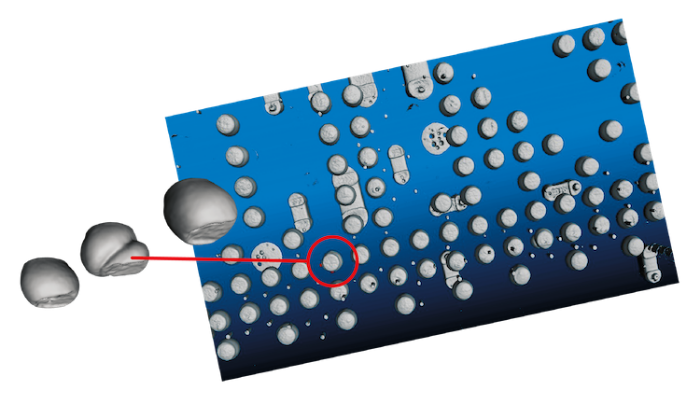

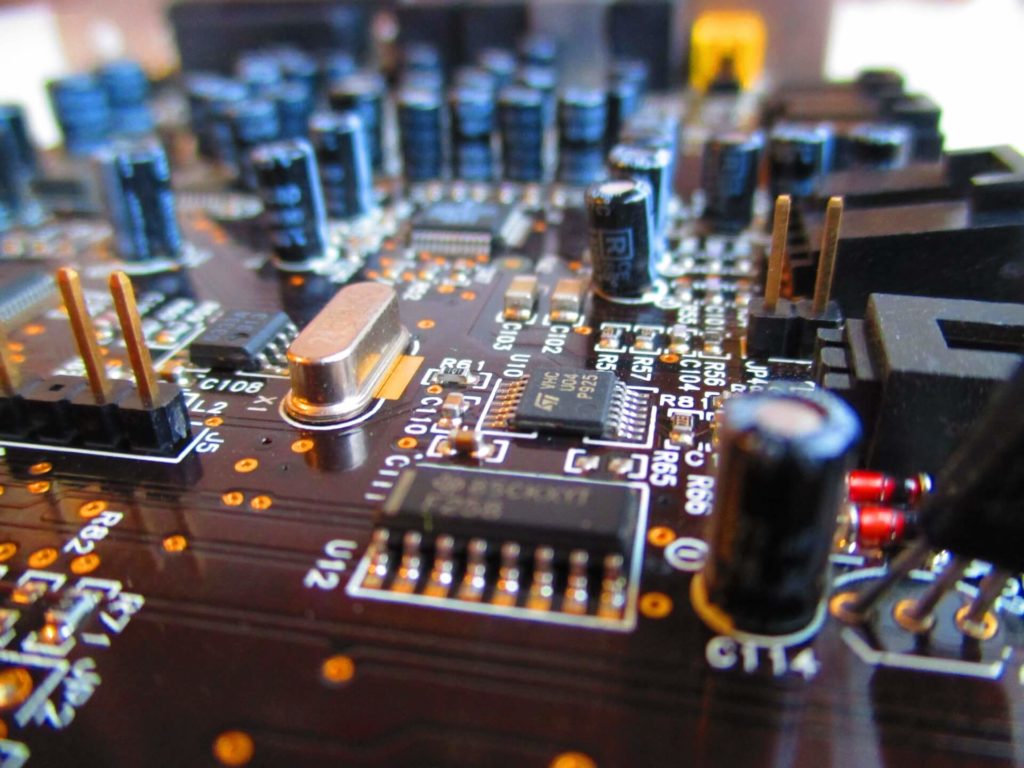

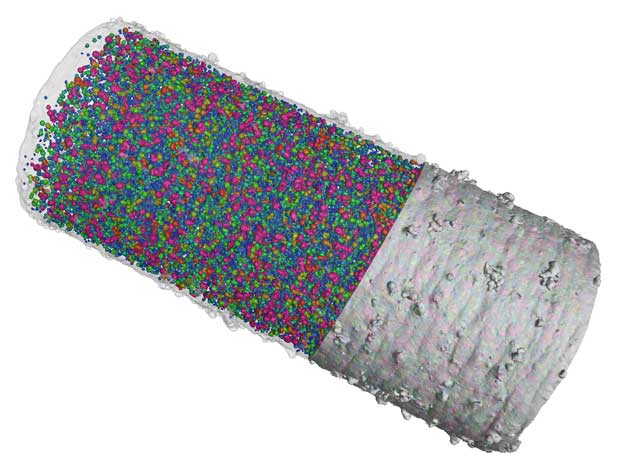

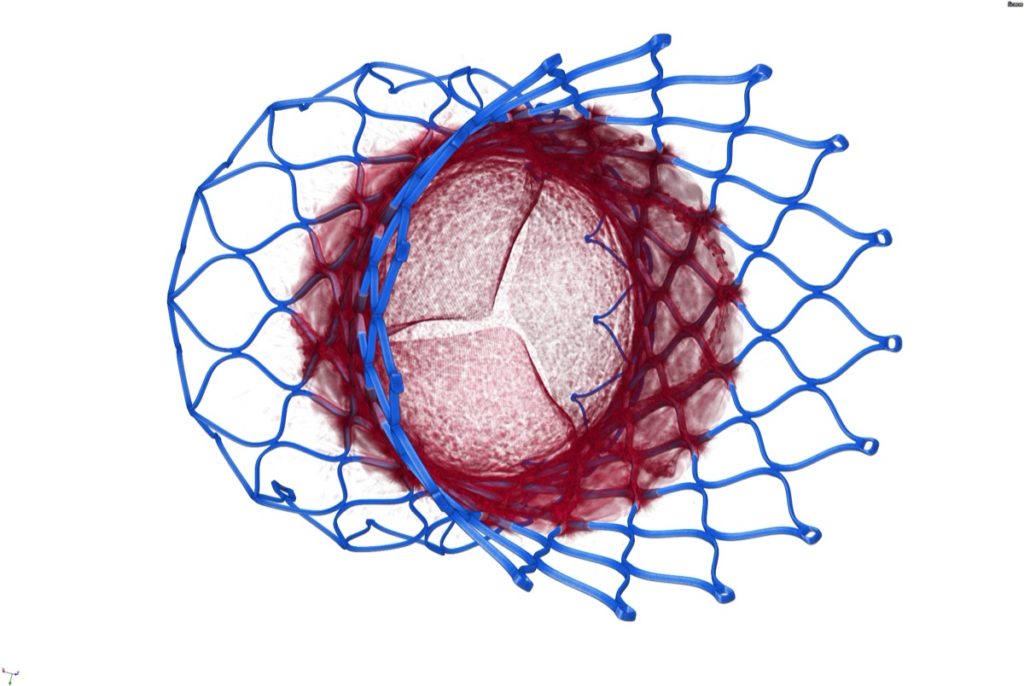

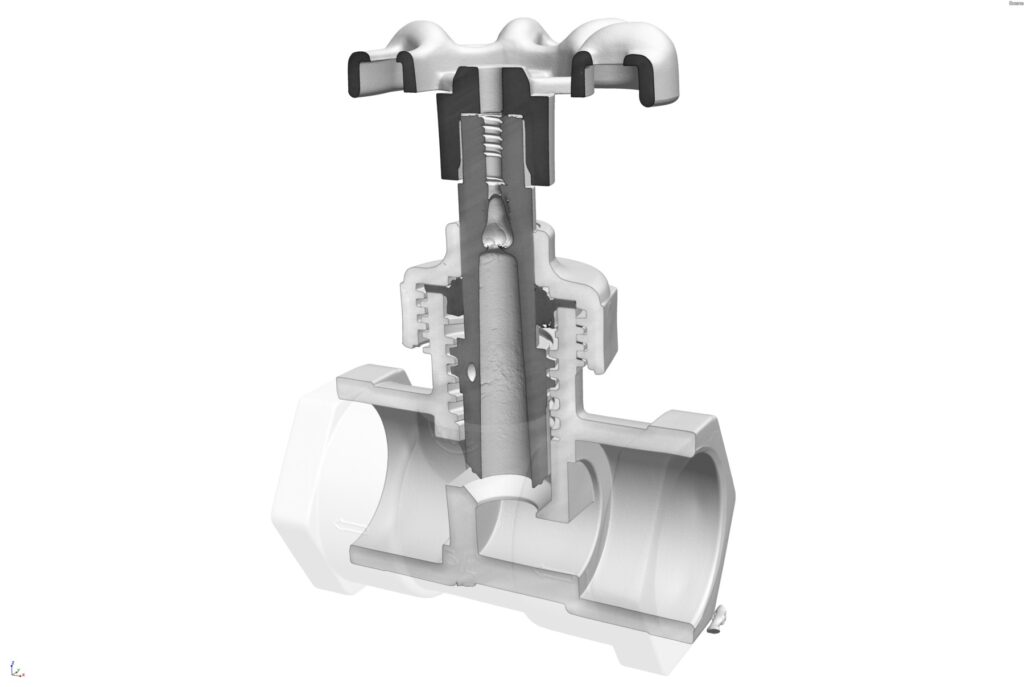

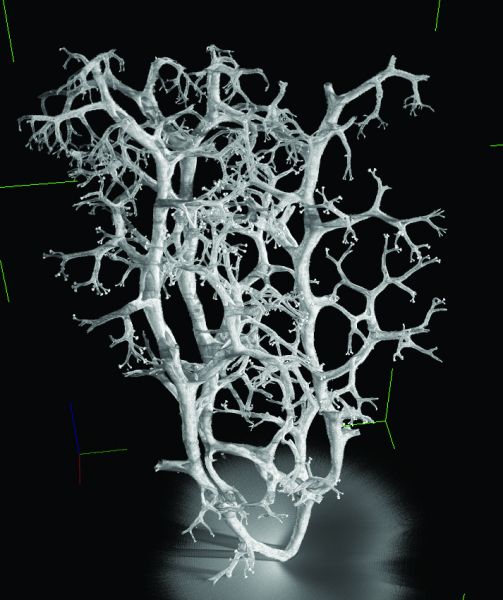

Applications include the inspection of small castings, plastic parts and complex mechanisms as well as researching materials and natural specimens. Anywhere the internal structure matters, X-ray and CT technology serves as an efficient tool to provide valuable information. Detailed capture and measurement of internal features is often vital for quality control, failure analysis and material research across various industries.

Productivity without compromise

- Half.Turn CT for faster CT acquisition

- Unique rotating target

- Auto.Filament Control and Quick.Change

- Local.Calibration, high accuracy CT measurements

- X-ray source for every application

- Automation and integration

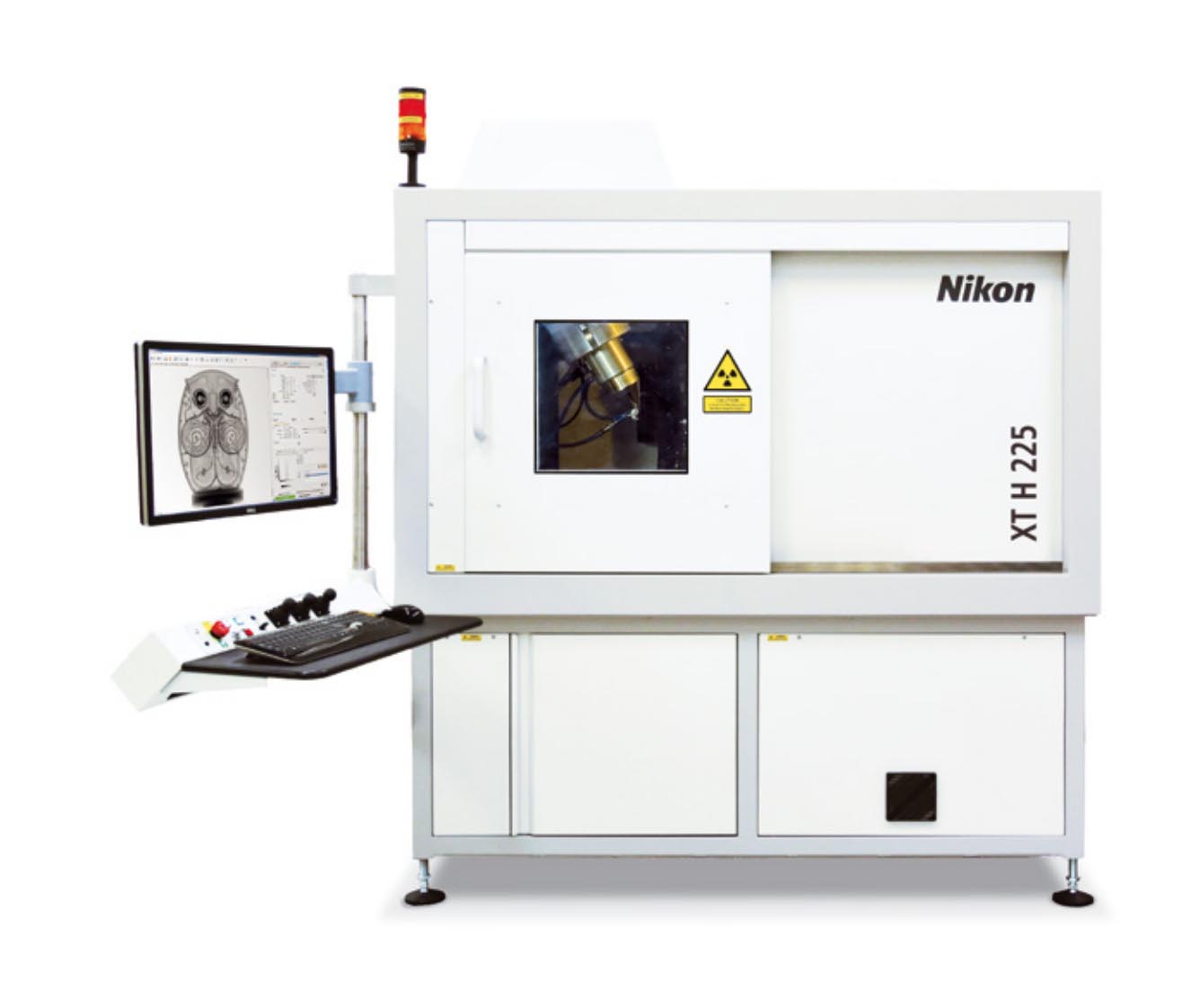

XT H 225

Detailed capture and measurement of internal component and assembly features is often vital for quality control, failure analysis and material research. XT H 225 offers a powerful micro-focus X-ray source, a large inspection volume, and high X-ray and CT imaging resolution. XT H 225 suits a wide range of applications, including inspection of small castings, plastic parts as well as material research.

XT H 225 ST 2x

The integration of industry-leading features into the XT H 225 ST 2x microfocus X-ray CT system allows a doubling of data acquisition speed and hence of inspection productivity. It is a result of using advanced detector technology combined with new functionality including Half.Turn CT and Rotating.Target 2.0.

XT H 450

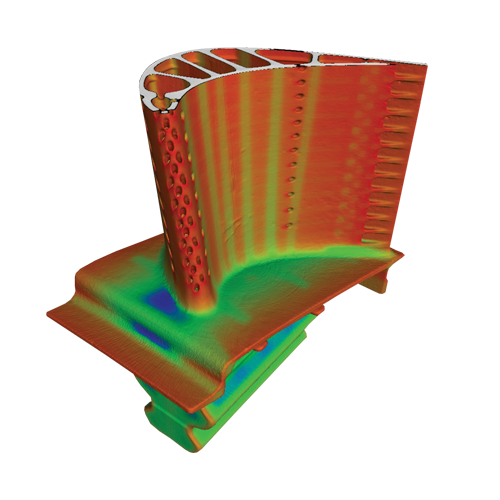

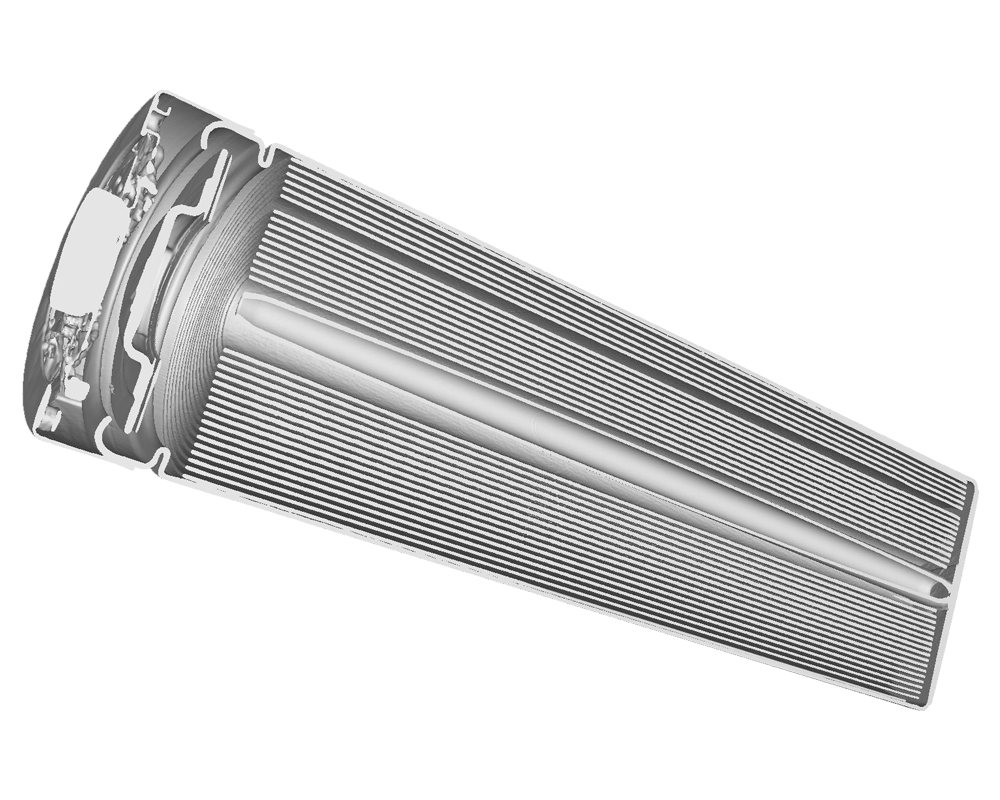

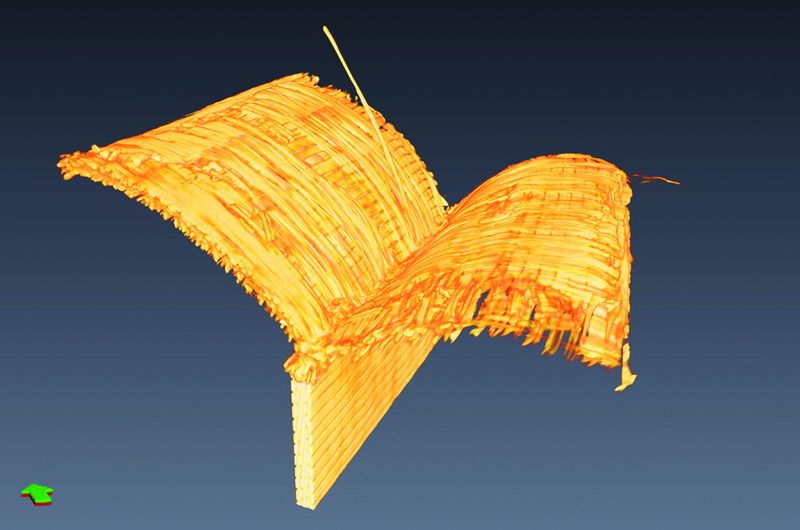

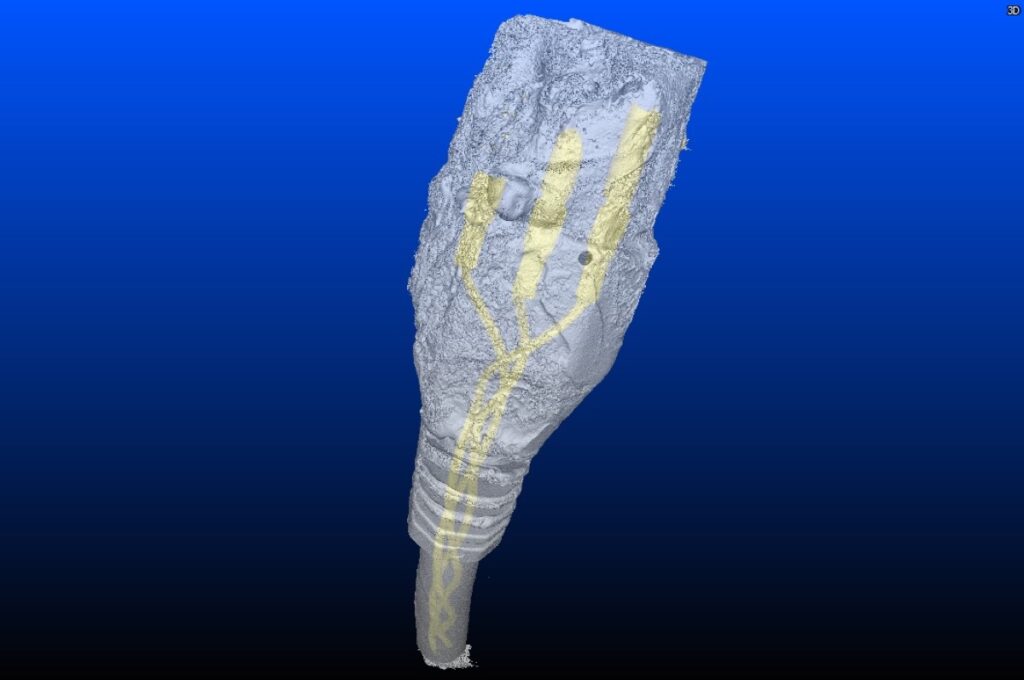

The XT H 450 system offers the necessary source power to penetrate through high density parts and generate a scatter-free CT volume with micron accuracy. The system is available with a flat panel or a proprietary Curved Linear Array (CLA) detector that optimizes the collection of the X-rays without capturing the undesired scattered X-rays.

The linear detector realizes stunning image sharpness and contrast by avoiding image pollution and associated contrast reduction. The 450kV and the CLA are ideal for the inspection of small to medium metal alloy turbine blades and casted parts.