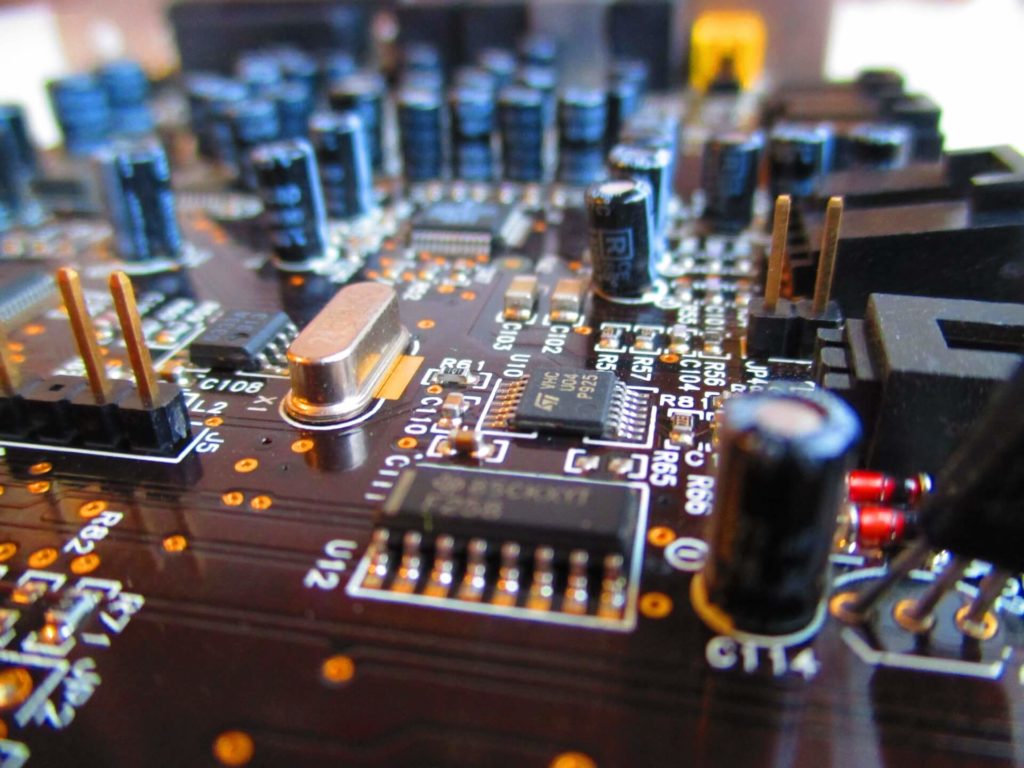

X-ray Scanning Inspection Services with Conform / Nonconform Determinations

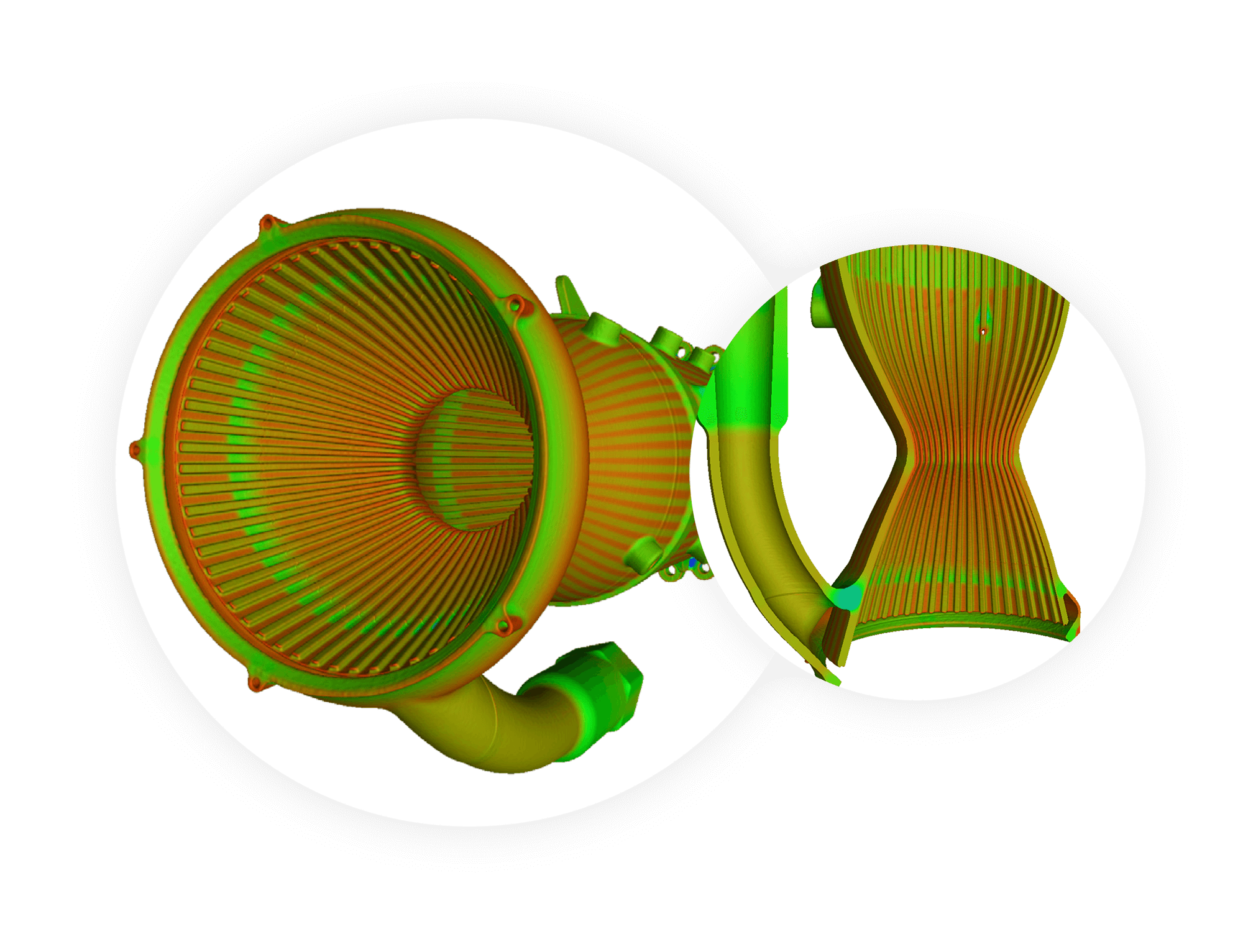

You Want Accuracy: Conform/Non-Conform Delivers It

Avonix Imaging can quickly and accurately make Conform or Nonconform Determinations based on your customer-provided inspection criteria or an existing published inspection standard, such as AWS D20.1, SAE AMS2175, or similar.

Whether you're looking for a certain certification level or you're up against a tight timeline, our µConform capabilities provide the compliance information you need.

Contact us today and speak with one of our Level 2 or Level 3 (NAS 410) staff to get started.

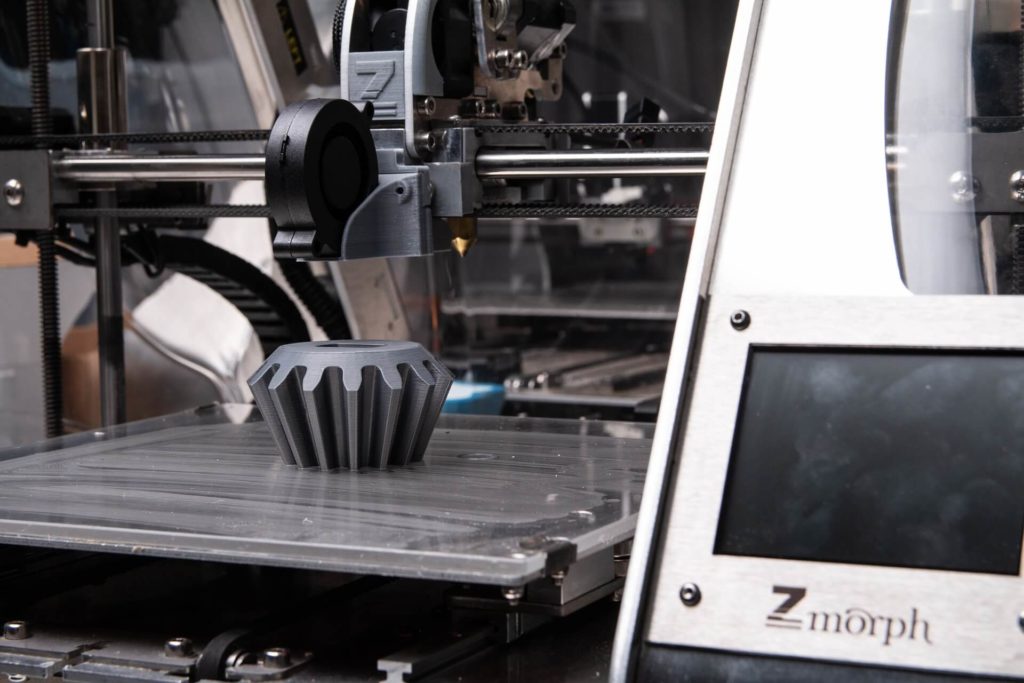

READY FOR THE MOST ADVANCED 3D IMAGING TECHNOLOGY?

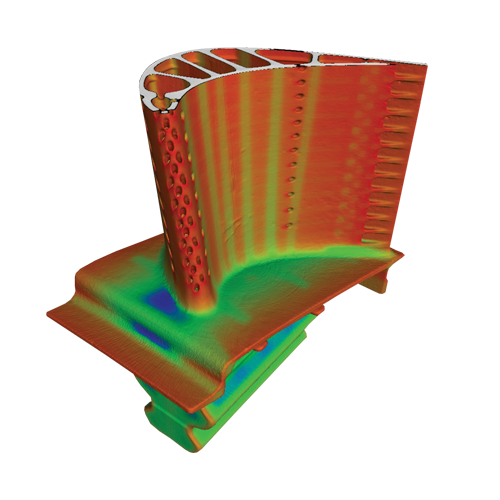

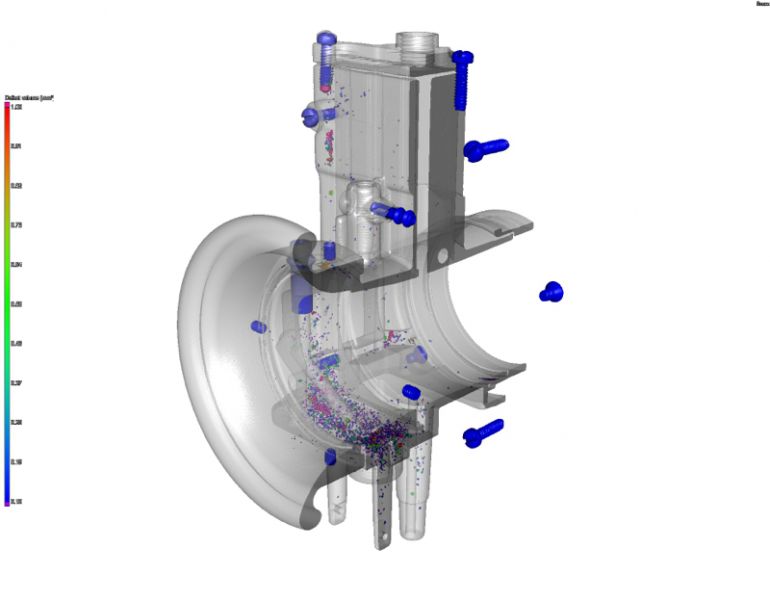

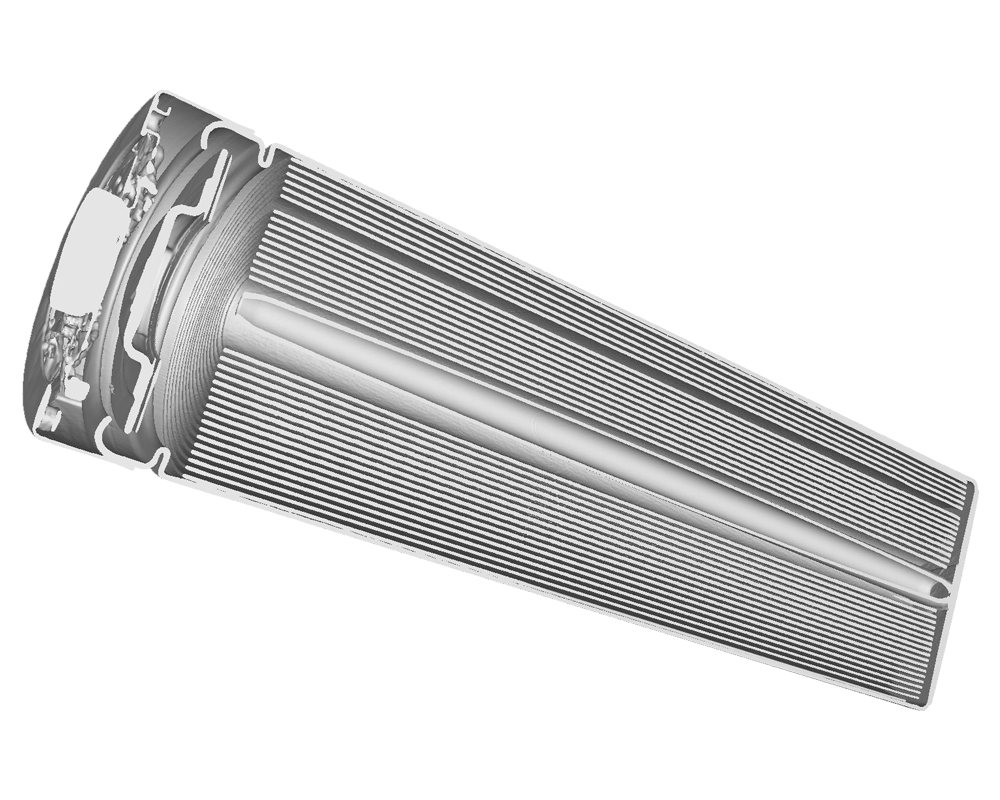

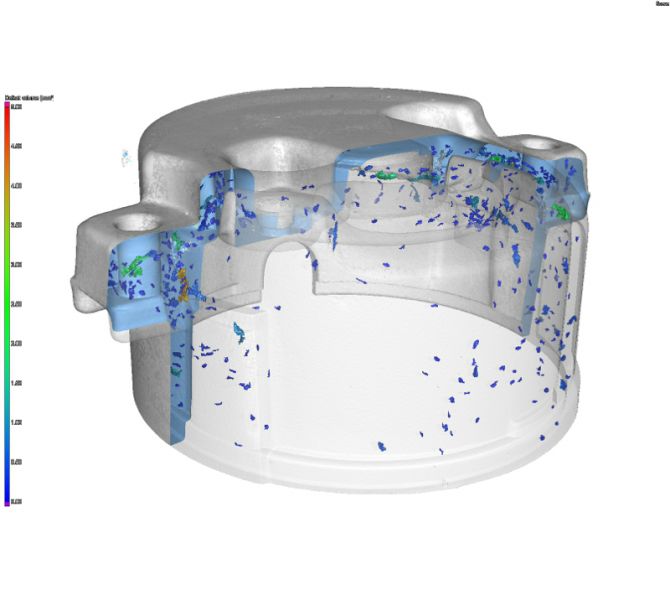

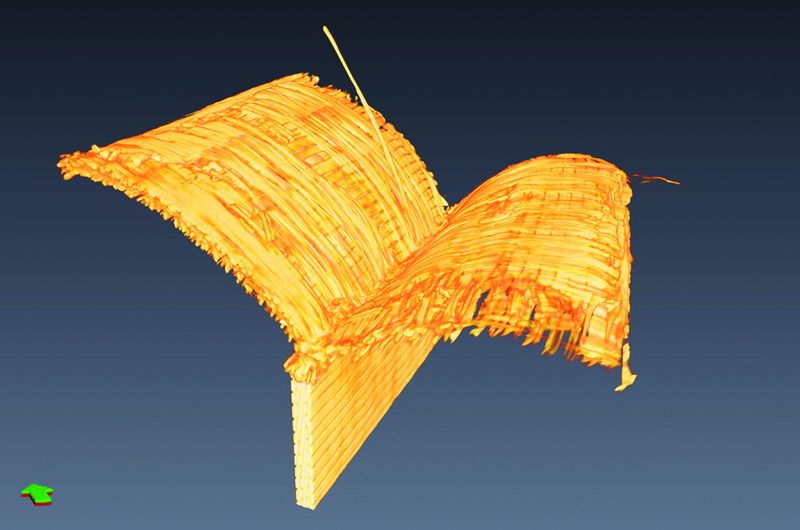

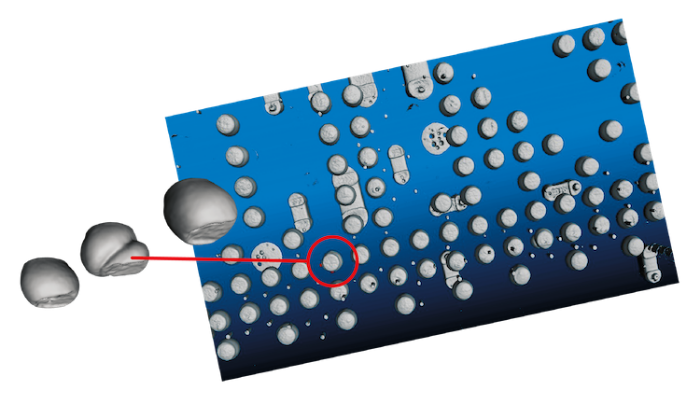

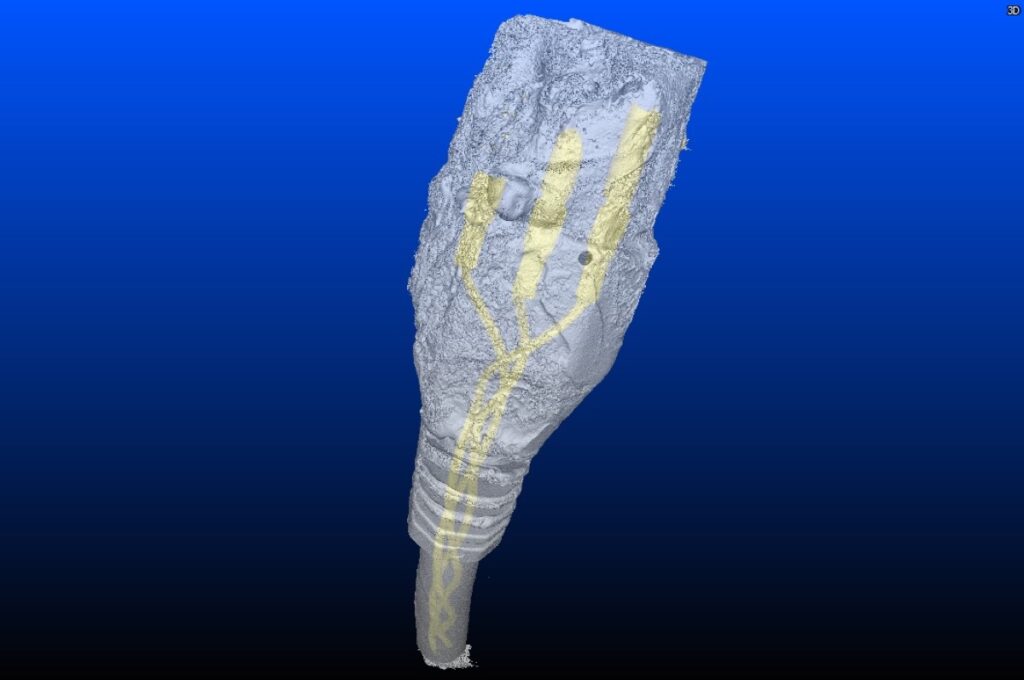

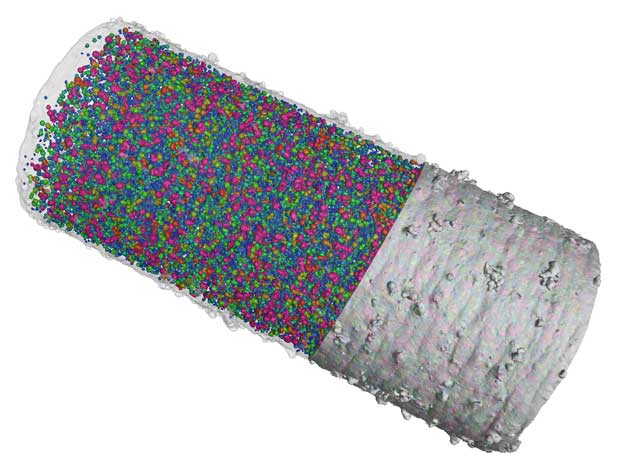

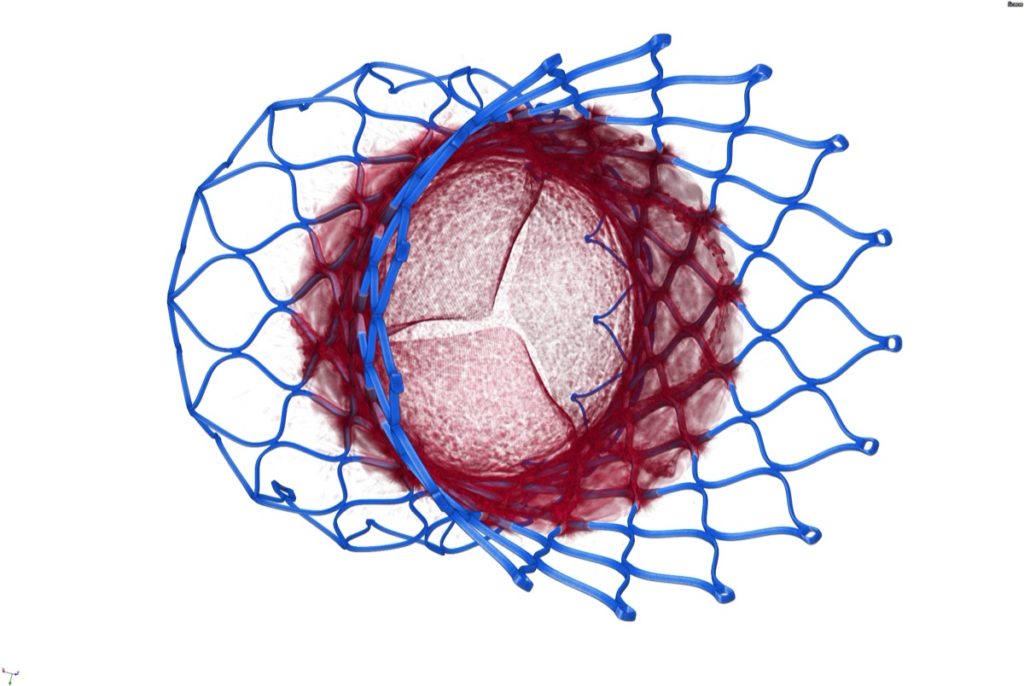

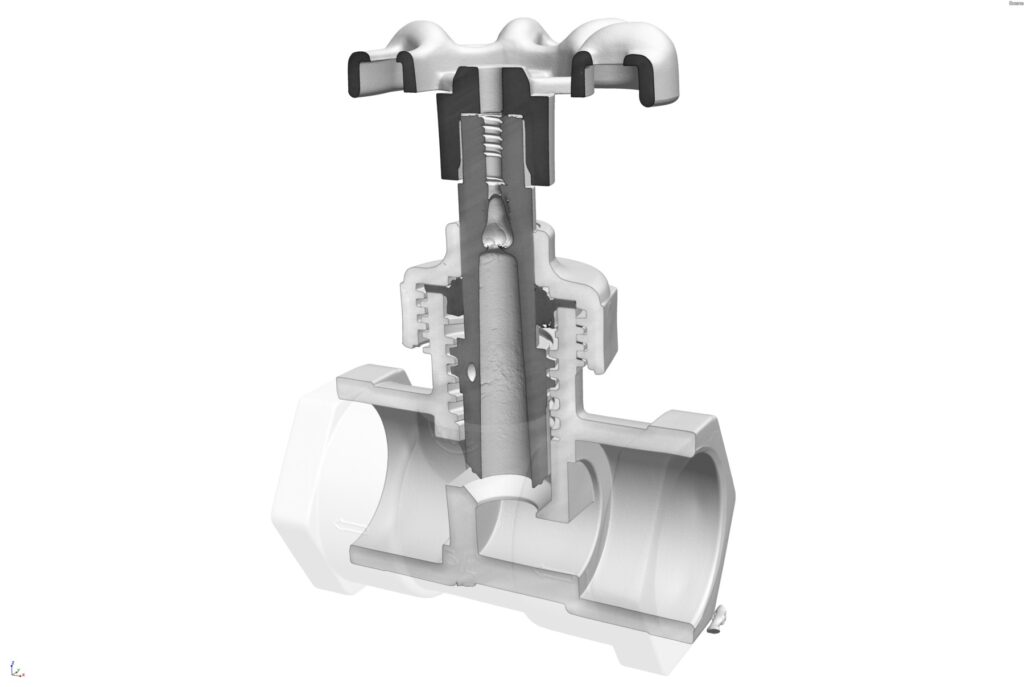

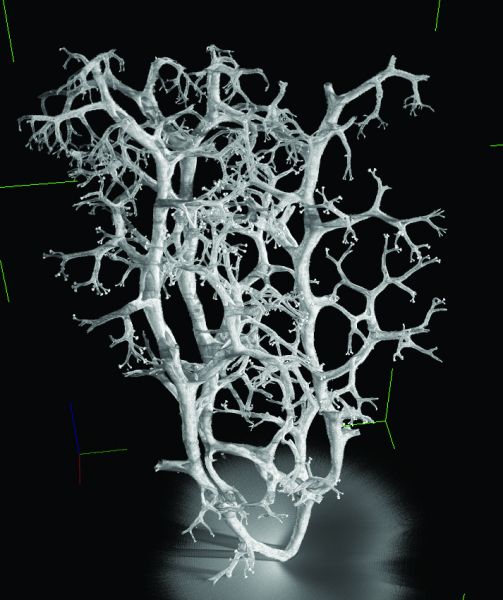

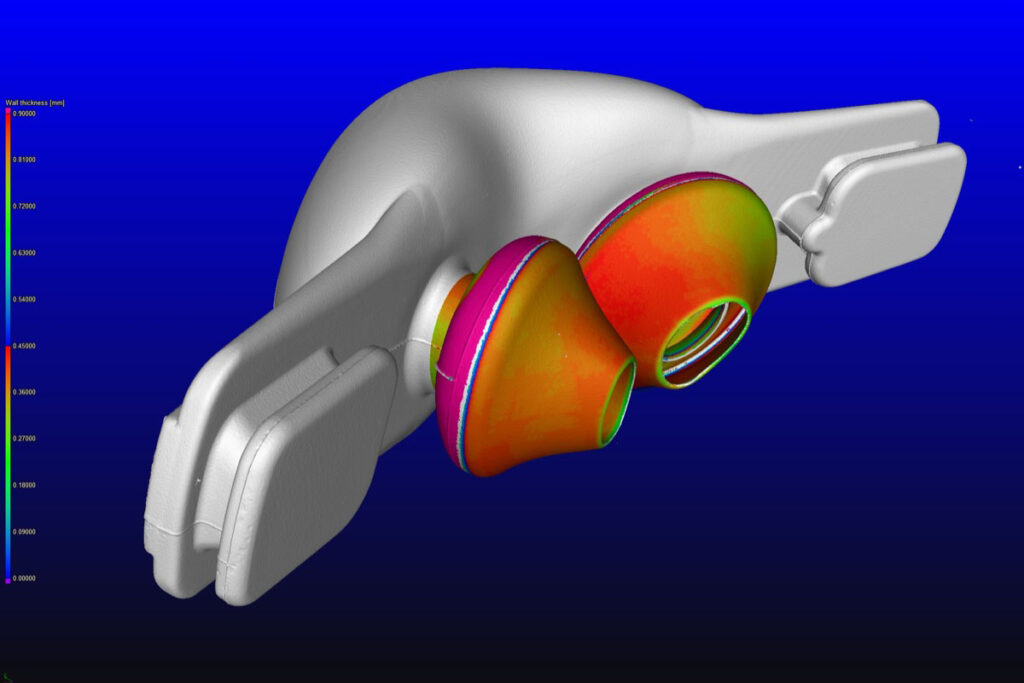

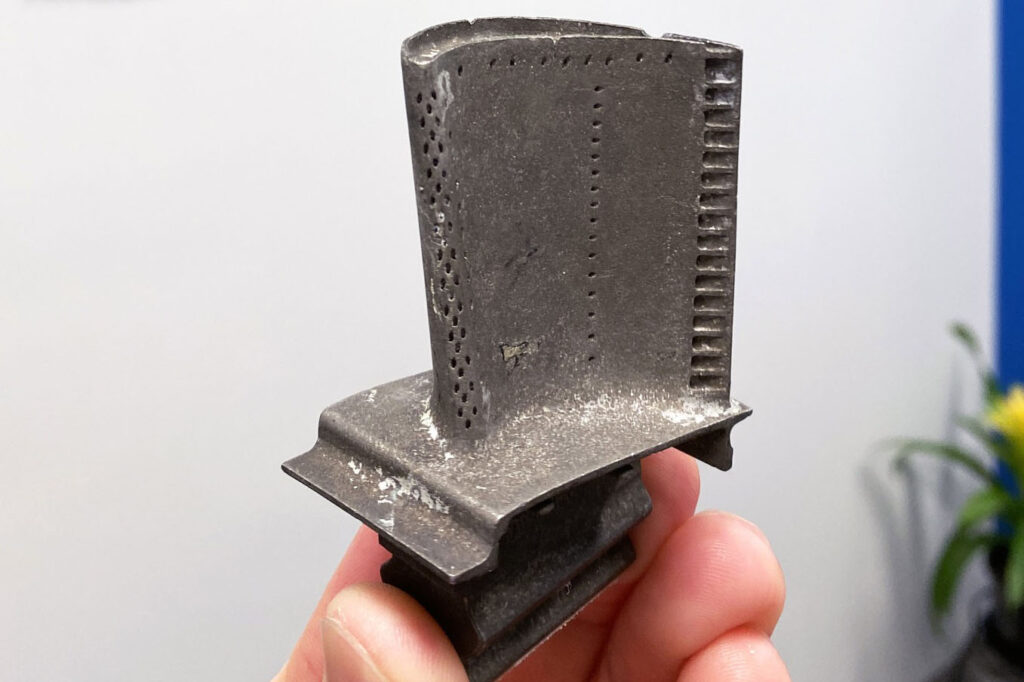

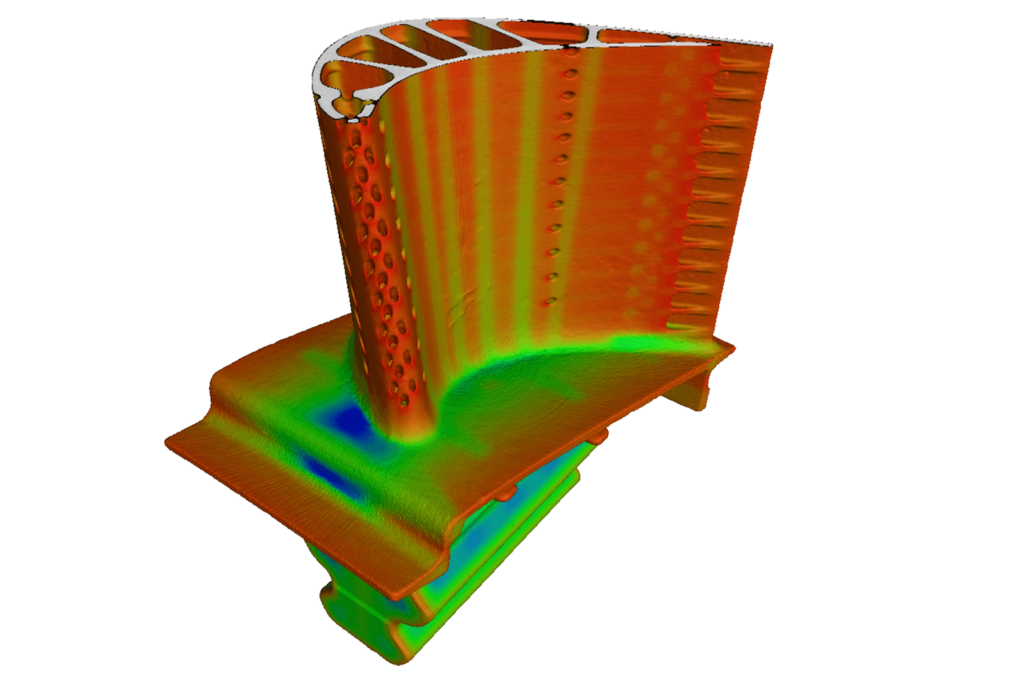

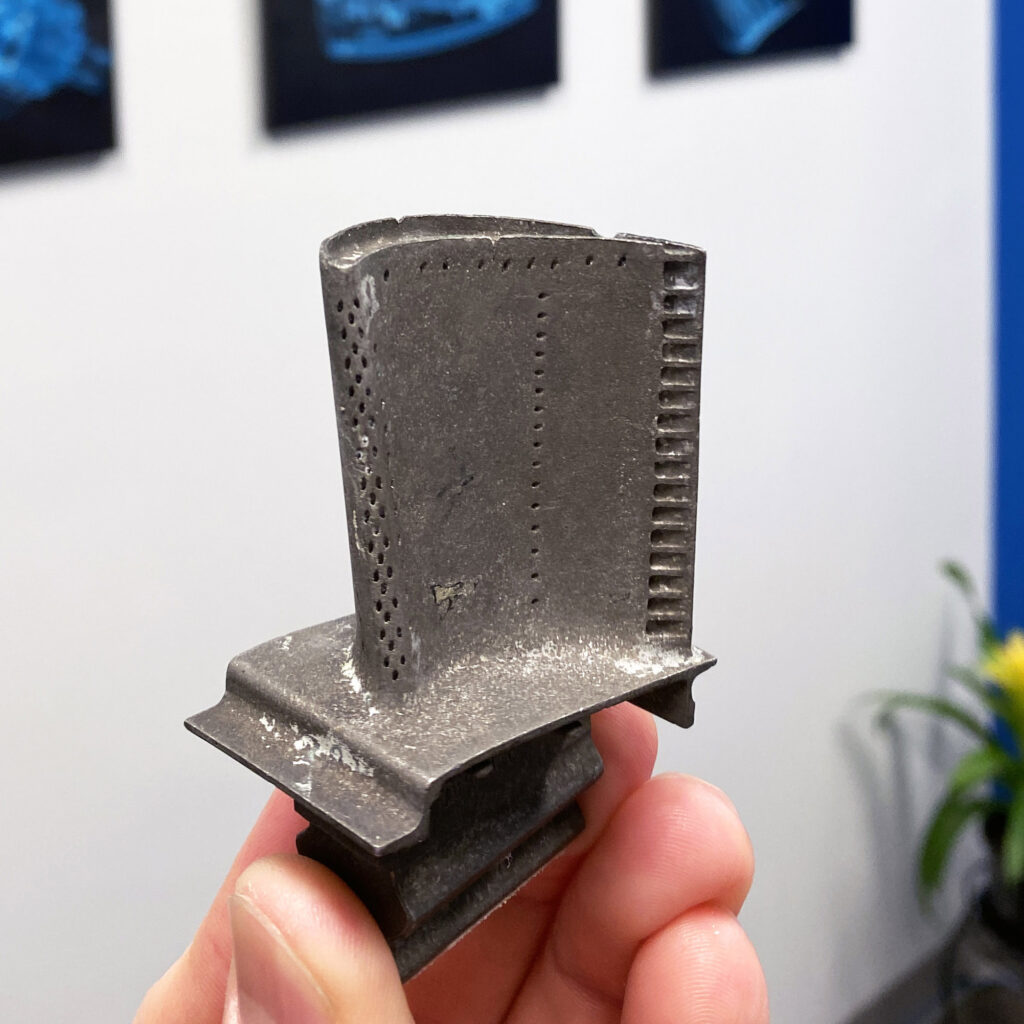

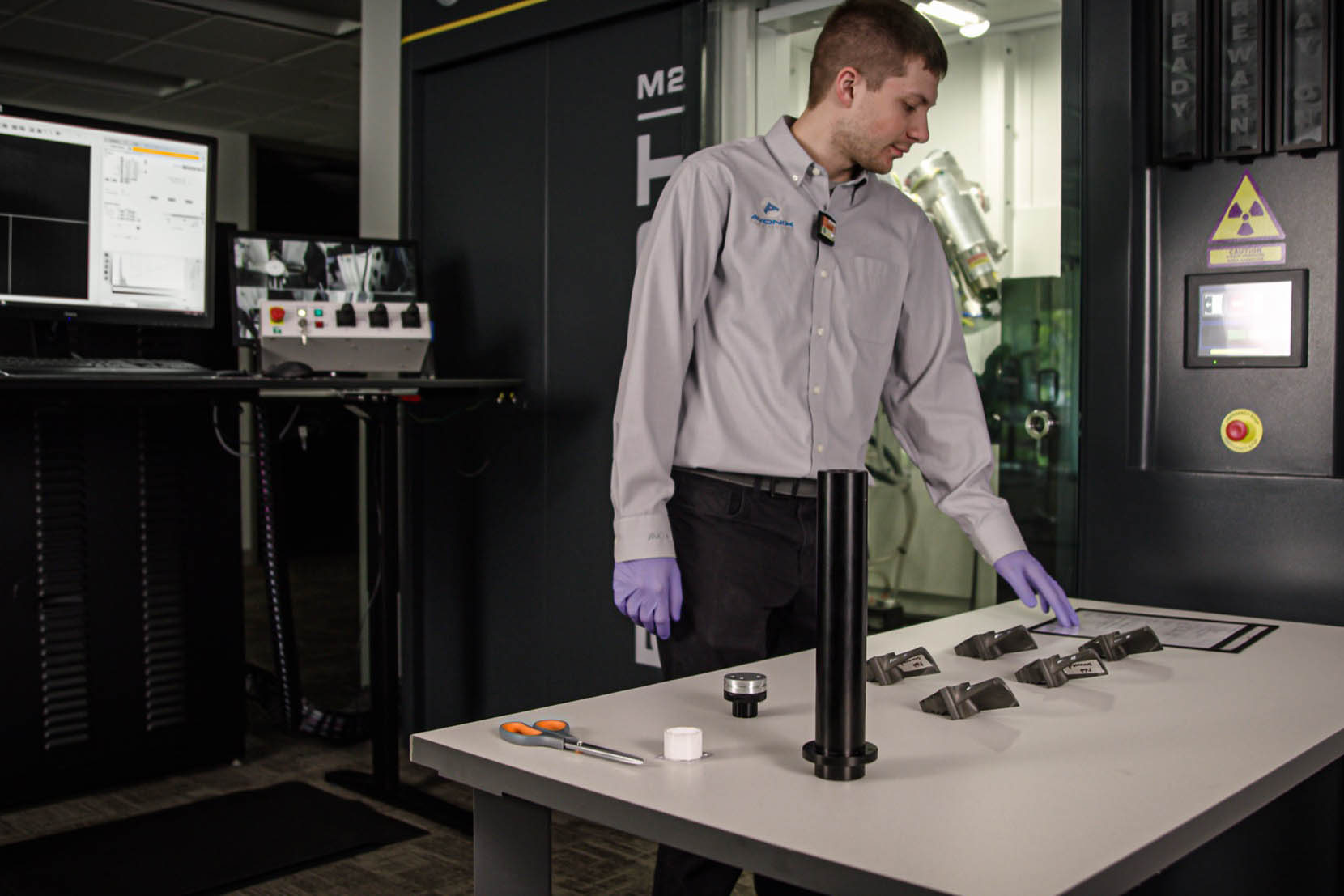

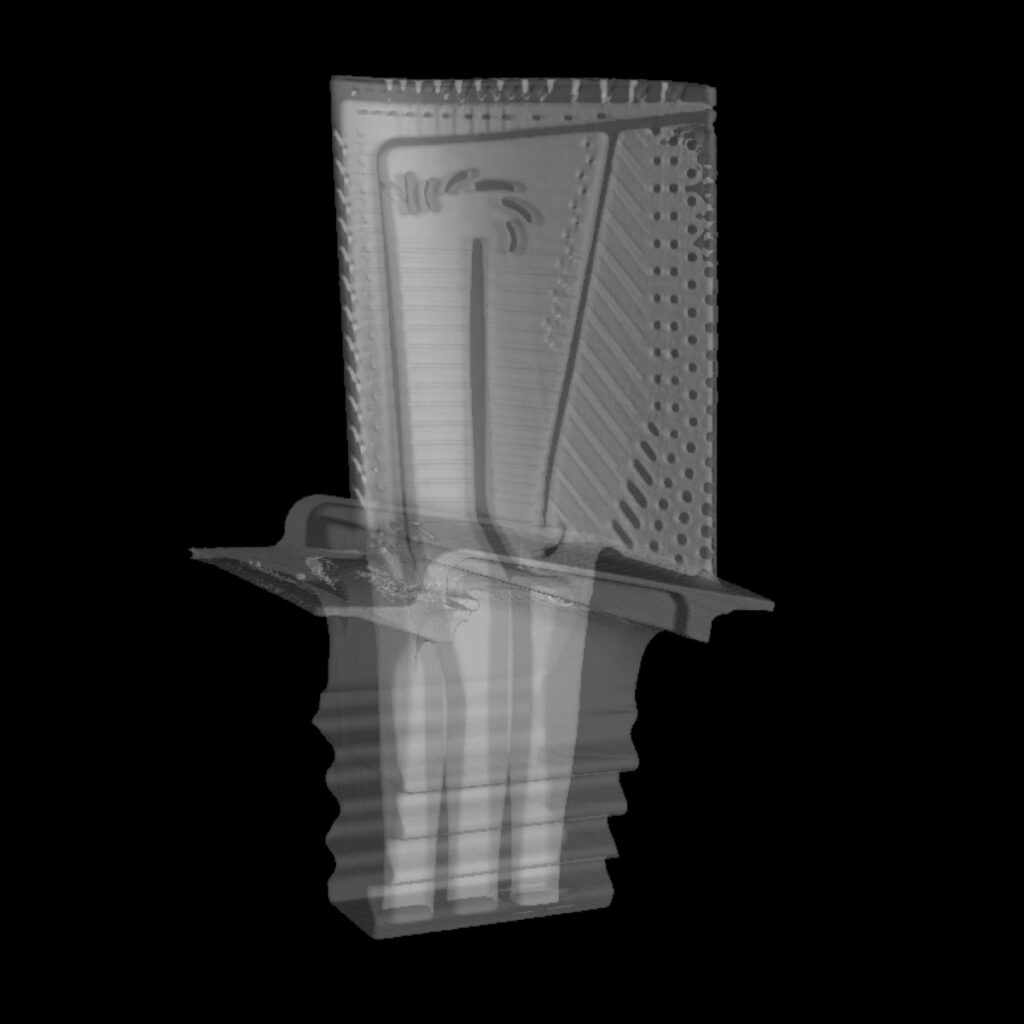

Computed Tomography (CT) is an x-ray methodology that yields 3-dimensional results. A sample is placed on a rotational stage, between the x-ray tube and the detector. The part is then rotated 360 degrees and images are captured at specific intervals, such as every degree or every half degree.

This series of images is then reconstructed to render the 3-dimensional x-ray model of the part. With CT visualization software, you can then slice through the part in any direction that you need to interrogate the internal configuration of the part.

READY FOR THE BEST PART? CT is the only way to get 3D views of the inside of a part and the only way to get true dimensional information without cutting it up.

Ready to Get Started?

3D CT scan results are easy to share across multiple departments and virtually eliminate interpretation errors. To get started, you can contact us directly by phone or fill out our online form.