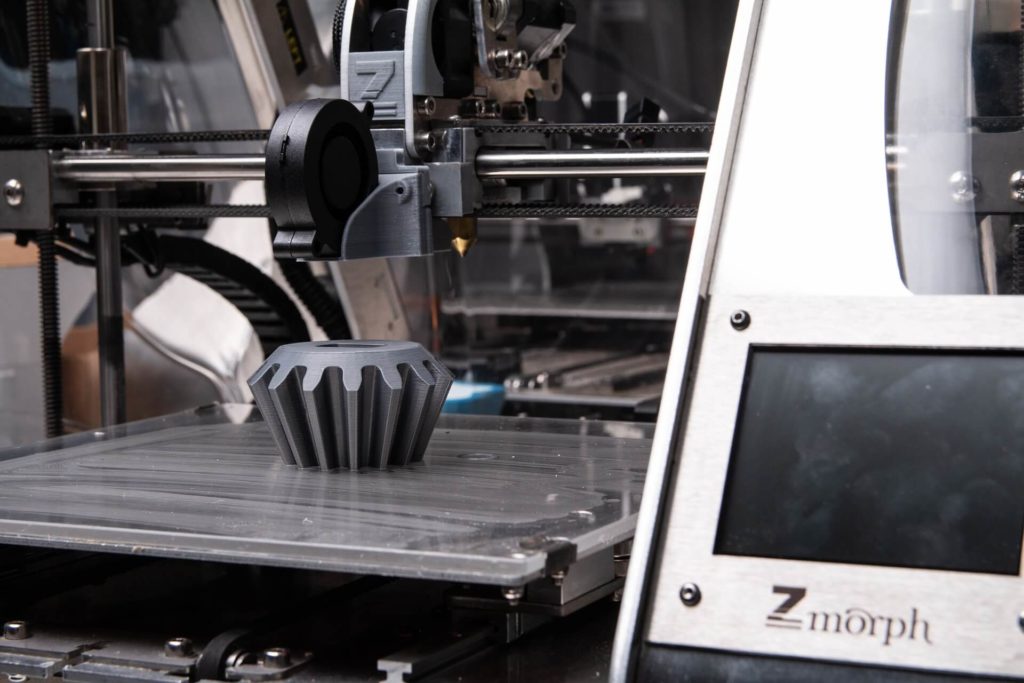

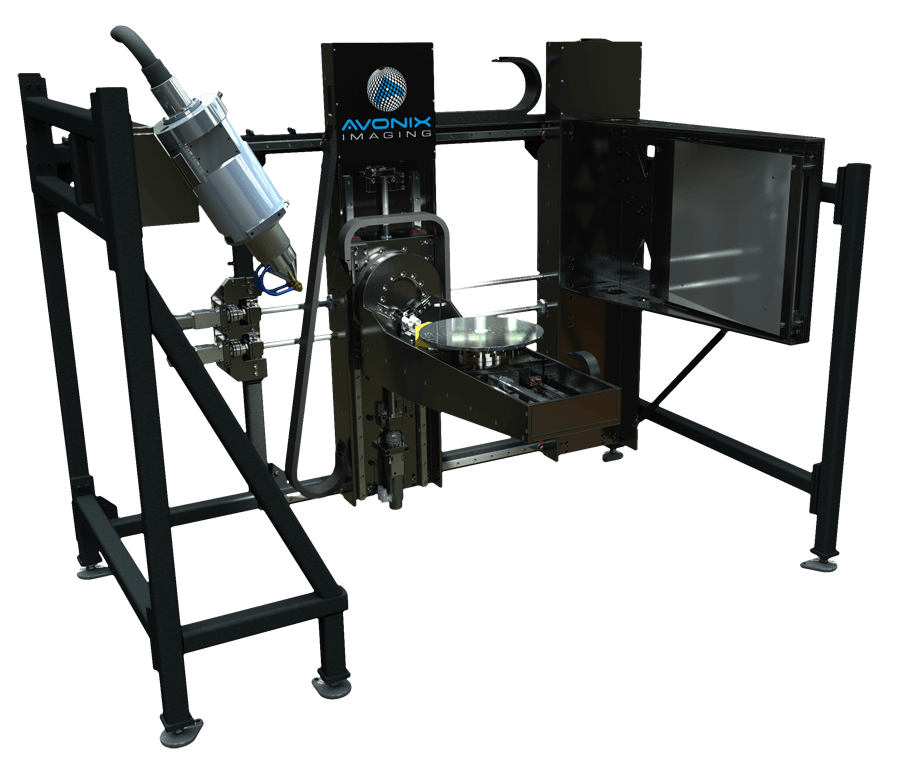

The Avonix E1 system is an economical, large-envelope modular inspection system.

The perimeter frame and cantilevered sample stage allows for free and clear access around the sample stage for ease of sample setup.

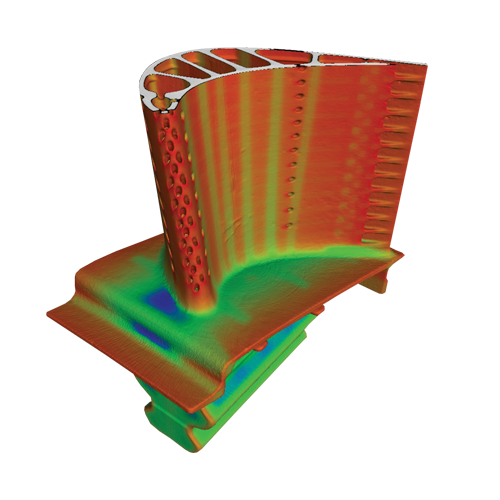

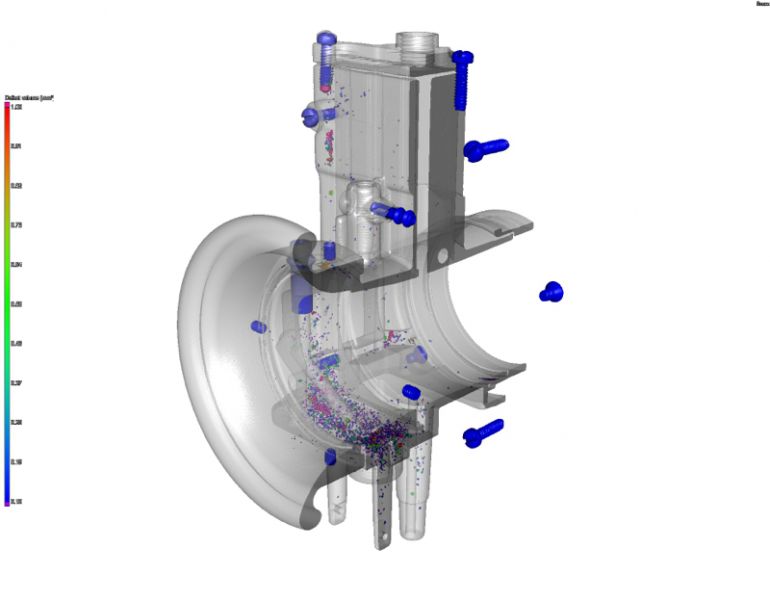

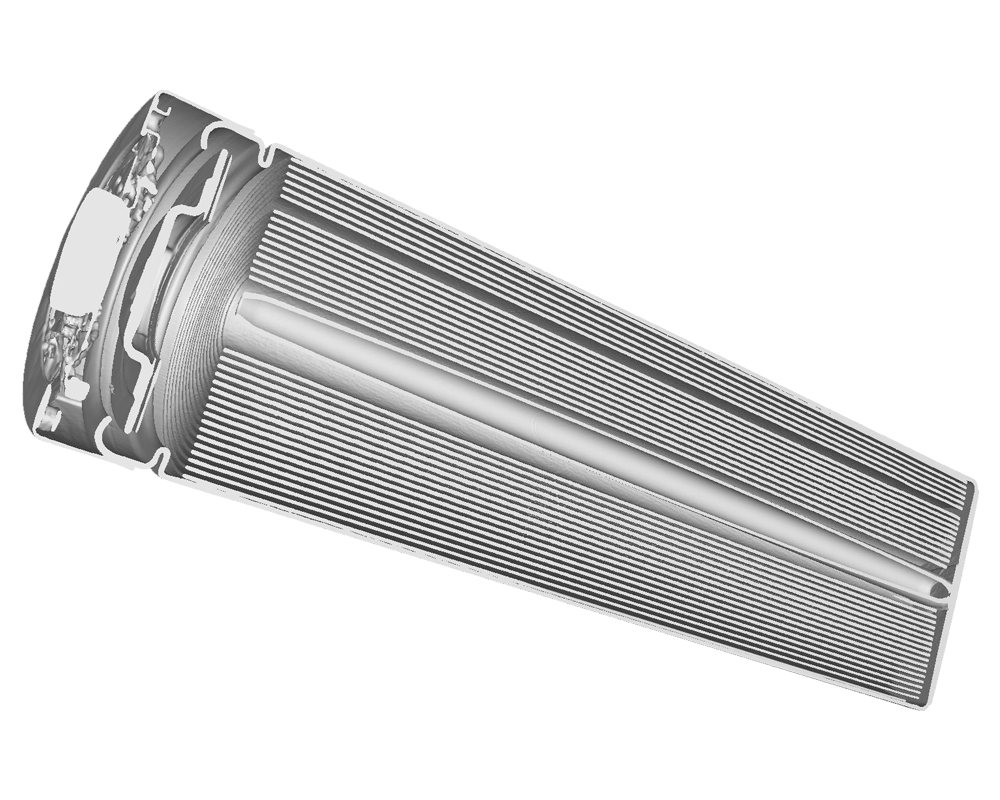

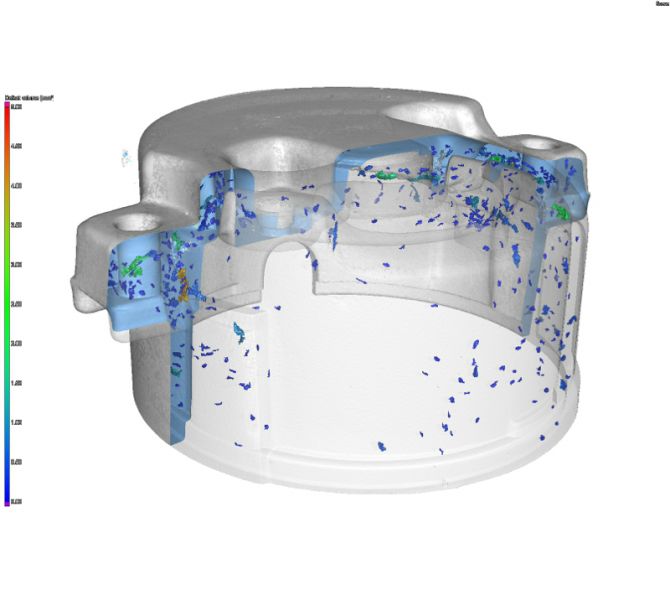

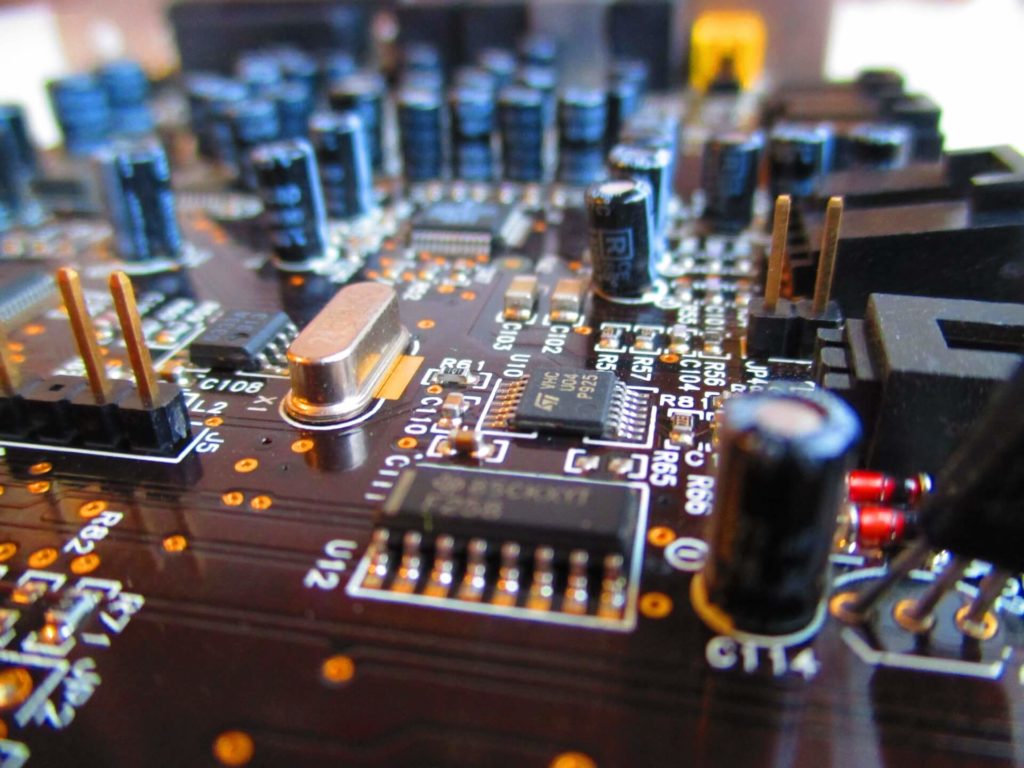

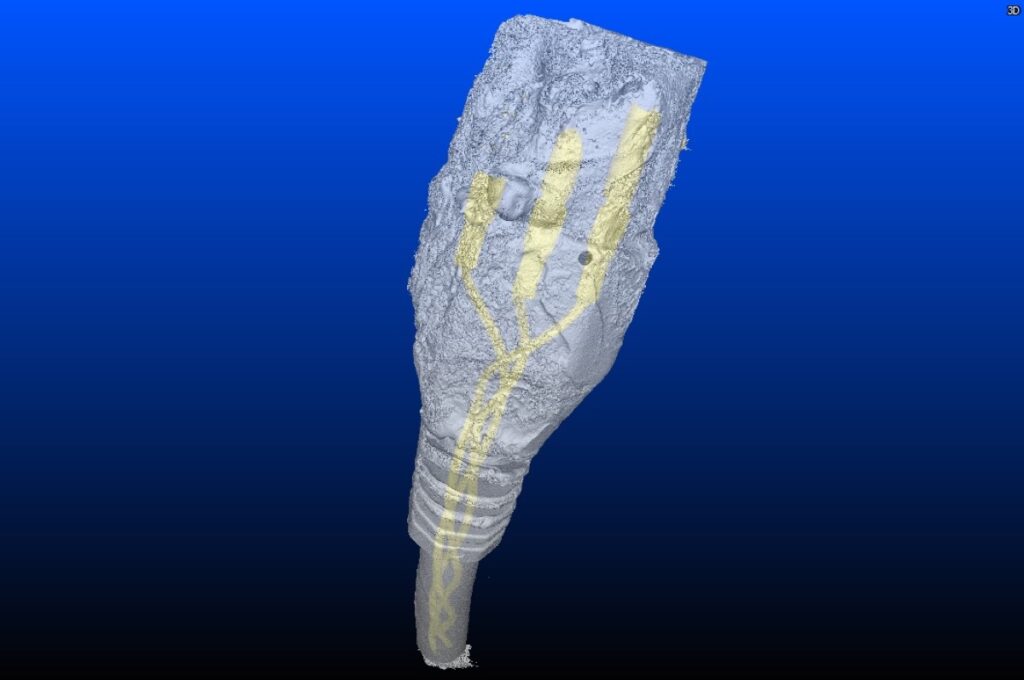

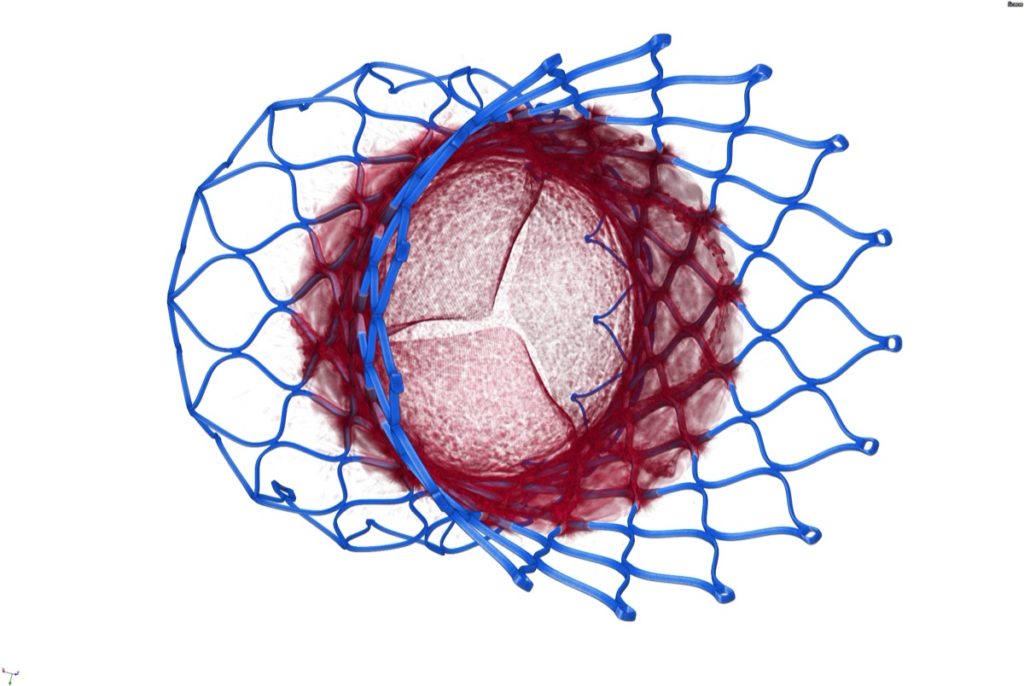

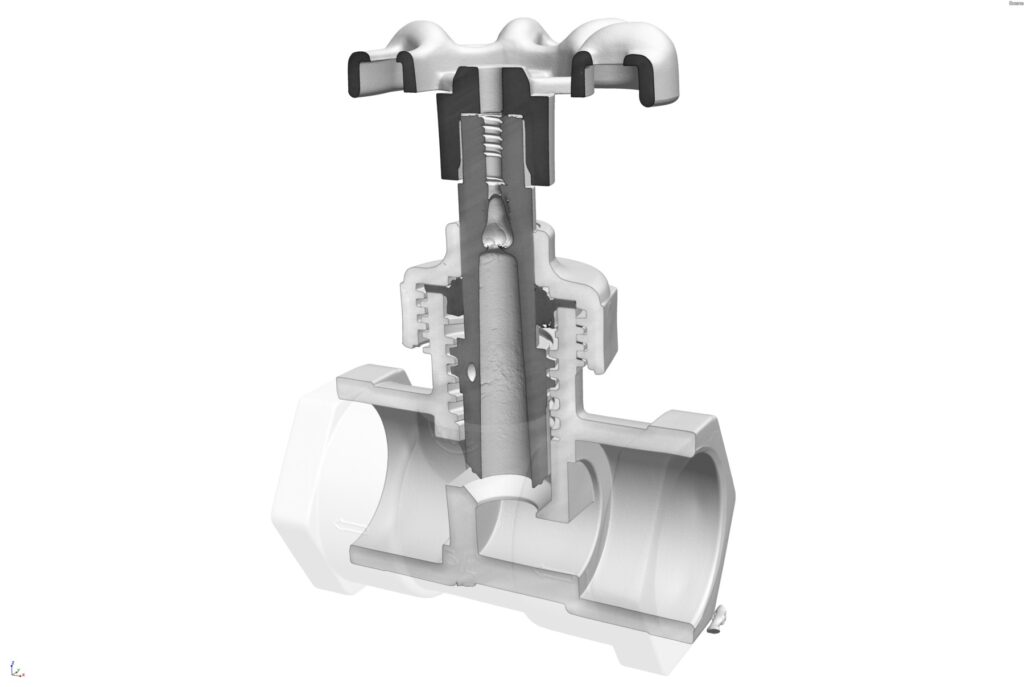

Supporting sources up to 450kV offers the necessary power to penetrate through high-density parts and generate scatter-free CT volumes with micron accuracy. The system is available with flat-panel detector technology and Nikon micro focus sources.

Large inspection envelope.

Large format 16-bit detector technology and image processing tools.

Patented X-ray tube technology. 225kV, 320kV and 450kV available.

Install into existing radiation enclosure or supplied with new modular radiation enclosure.

E1 Features

- Large inspection envelope

- Install into existing radiation enclosure or supplied with new modular radiation enclosure

- Patented X-ray tube technology. 225kV, 320kV and 450kV available

- Large format 16-bit detector technology and image processing tools

- Intuitive software interface

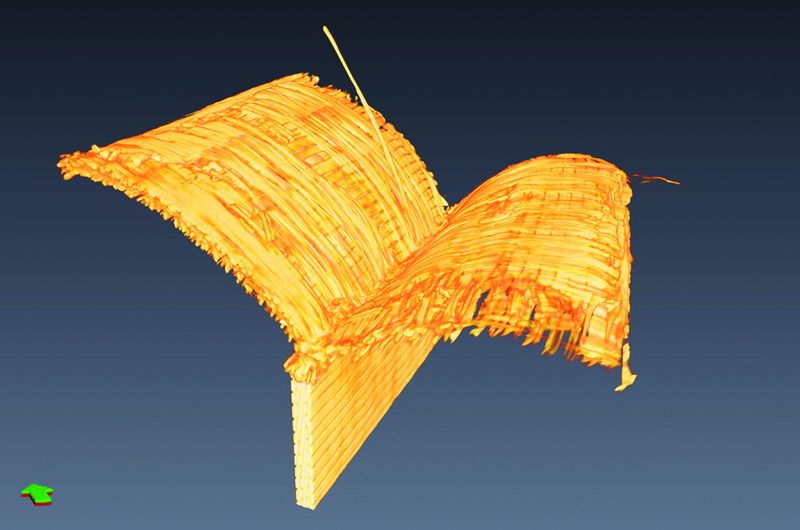

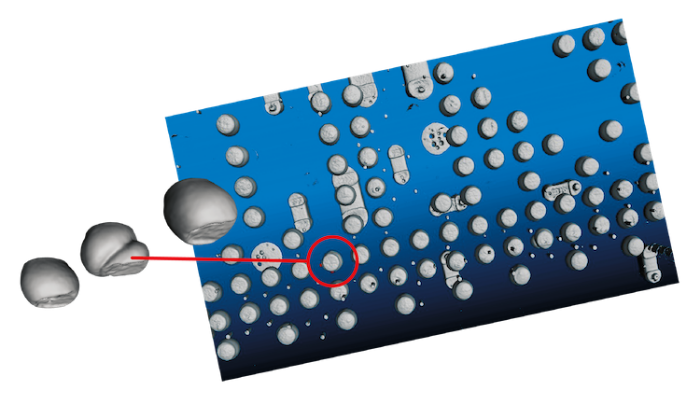

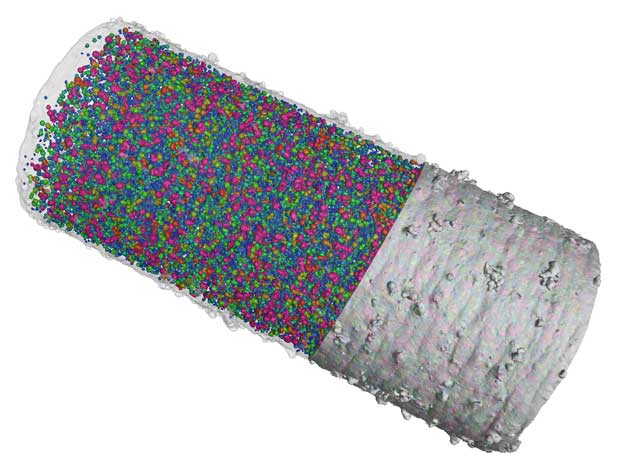

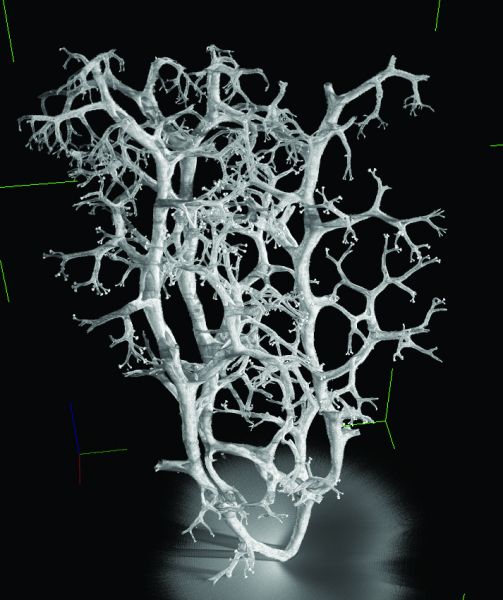

- Advanced 3D visualization and analysis

- Customizable macros to automate work flow