Written by David Harman, Ph.D., Simpleware Solution Account Manager with Synopsys in collaboration with Avonix Imaging.

Jet engine turbine blades are required to operate in extreme conditions, where operating temperatures can exceed the melting point of their alloys. As a result, complex cooling geometries, coatings, and other properties help keep blades within operational temperature, with failure not being an option. However, manufactured parts may contain small embedded and hidden defects. Computed Technology (CT) inspections allow us to inspect inside these parts.

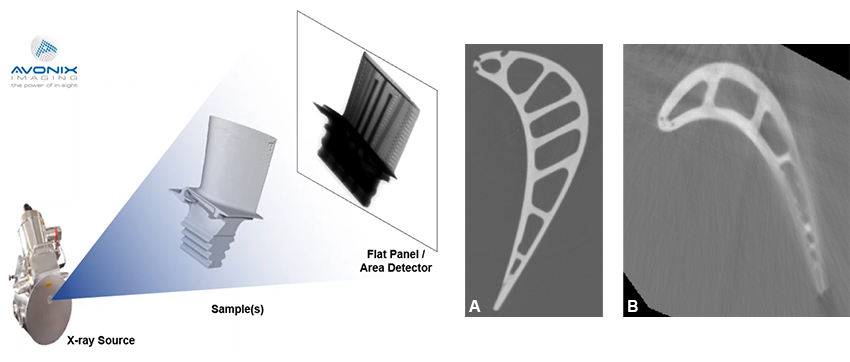

CT inspection is a nondestructive industrial x-ray process. The part in question rotates 360 degrees while hundreds or thousands of individual 2D radiographs are captured at specific degree intervals. By reconstructing these 2D radiographs into a 3D CT volume, they can be digitally sliced at any angle. Users can then inspect their product’s external and internal features without needing to physically cut or open it up.

One challenge with this workflow? The overall image quality dictates the ability to resolve defects and dimensions within the part. Image quality is often directly correlated with inspection cycle time. High-density and complex parts, including turbine blades, typically require significant scan and technician interpretation time. This can create a potential bottleneck for high-throughput applications.

Creating an Automated Solution Using AI

Synopsys Simpleware Custom Modeler offers a solution to the challenge of bottlenecks in manual image review through case-specific analysis with AI-enabled Machine Learning methods. This approach eliminates time-consuming manual segmentation time from the work; the pre-determination of defect locations reduces inspection time. Further scaling up of inspection is therefore only dependent on the power of the hardware used for the assessment. Collaborating with Avonix Imaging, we developed a project to detect low-frequency critical defects in high-pressure turbine blades to create a fully automated inspection assistant to highlight possible defect regions and speed up critical inspection workflows.

Obtaining Input Data

X-ray CT technology has seen a lot of great innovation in recent years. Expanded capabilities through scanning methods like Pixel Push, Helical CT, Offset CT, and even hardware improvements, including Heat Dissipating Rotating Targets and 450kV Microfocus tubes, have been instrumental in the growth of CT scanning across many industries. Frequently, 3D CT scanning can provide a view that users cannot obtain any other way.

Each company’s specific needs and project goals dictate the ideal CT method and technique. CT technicians must consider a product’s material, density, size, shape and features, defect size requirements, scan time goals, and the desired output format.

Once goals and product details are understood, a scan technique can be developed. The most common hardware parameters used with industrial CT are:

- x-ray energy (225kV or 450kV)

- focal spot size (mini-focus or micro-focus)

- detector type (LDA or DDA)

From there, part fixturing, geometric magnification, and manipulator positioning (source to part, source to detector, etc.) are set. Finally, acquisition methods, number of projections, and other fine-tuning adjustments are made before running the CT scan.

For this project, the turbine blades’ high density led to the selection of the 450kV micro-focus tube. Both an LDA and DDA detector were tested. Avonix Imaging performed several high-quality LDA scans and a sample of high-speed scans using a DDA detector on the same set of turbine blade samples to develop an ideal reference scan. Sample run scan times ranged from a few minutes to many hours. This underscores the importance of understanding project goals and finding a technique that effectively meets those goals.

Running an Automated Workflow

With the CT scanning process optimized for efficiency, we developed an automated inspection workflow.

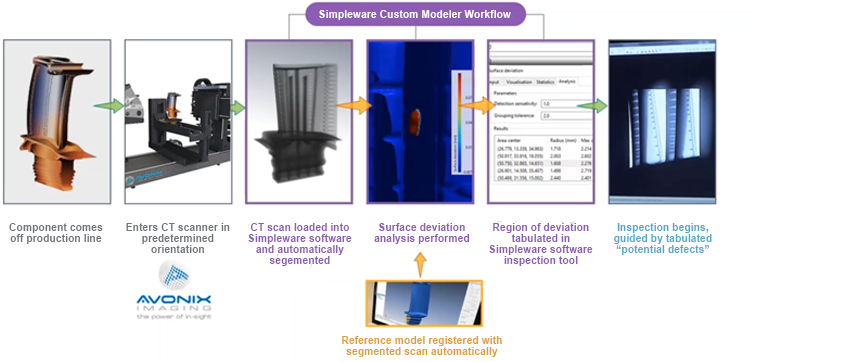

In practice, once a component comes off the product line, the automated workflow goes as involves:

- Enter a CT scanner in a predetermined orientation for inspection-speed scanning, typically next to a production line

- Load the CT scan into Simpleware software and run the Simpleware Custom Modeler AI-enabled workflow:

-

- The CT scan is automatically segmented into regions of interest based on training data from an expert user

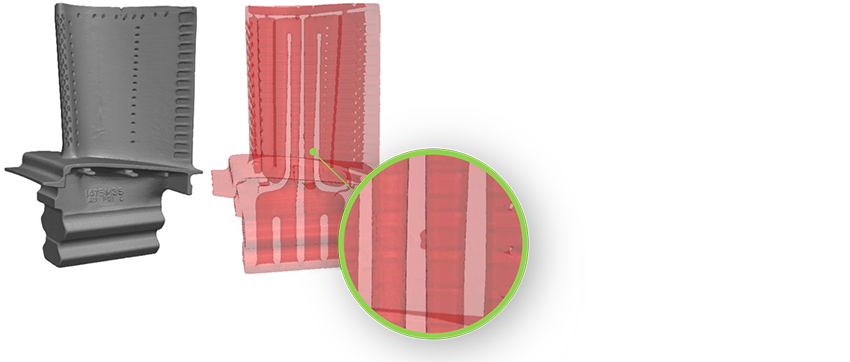

- Surface deviation analysis is carried out. The “ideal” reference model is registered with segmented scans automatically

- The region of deviation between the two models is tabulated using an inspection tool, with sensitivity adjusted based on the examined defects

-

- Carry out inspection using tabulated “potential defects”

This customized automated workflow allows rapid defect defection for high-volume manufacturing. This reduces the need for time-intensive manual segmentation.

Video Demo of Simpleware Software performing Automated Defect Detection for Turbine Blades:

Future Impact

The automated workflow developed with data from Avonix Imaging demonstrates the potential to solve bottlenecks associated with inspection for high-value parts such as jet engine blades. In addition, the methods used in Simpleware Custom Modeler can be easily extended through ‘bolt-on’ additional measurement strategies for further analyses.

Example measurements include GD&T-style measurements, wall thickness, and centerline cross-section analysis. This method aims to aid inspectors by providing augmented data, including preliminary locations of interest to evaluate. This approach can ease the inspection process and reduce overall inspection time, resulting in more efficient production lines for manufacturers.

Watch the Full Webinar

Watch the full webinar Lifting the Burden of Manual CT Inspection for Turbine Blades with Simpleware AI Solutions to dive deeper.

To learn more about Simpleware and their 3D Image Processing Solutions, visit: https://www.synopsys.com/simpleware/software.html

View original blog post on Synopsys website.

Request Service

Curious about how Axonix Imaging can help your industry? Contact us using the form below.