Written by:

Jeremiah Shoemaker

Inspection Services Technician

For as long as I can remember, I’ve been a fan of trains. So, it follows that my hobby outside of work here at Avonix is model trains.

The model trains I collect are known as N-scale. The model is 1:160, or 160 times smaller than the real thing. The distance between railheads on a full-size locomotive is 4ft 8.5in, whereas the distance on the N-scale models is only 9mm. While N-scale models are not the smallest scale produced, working on these trains requires good eyesight, steady hands, and magnification.

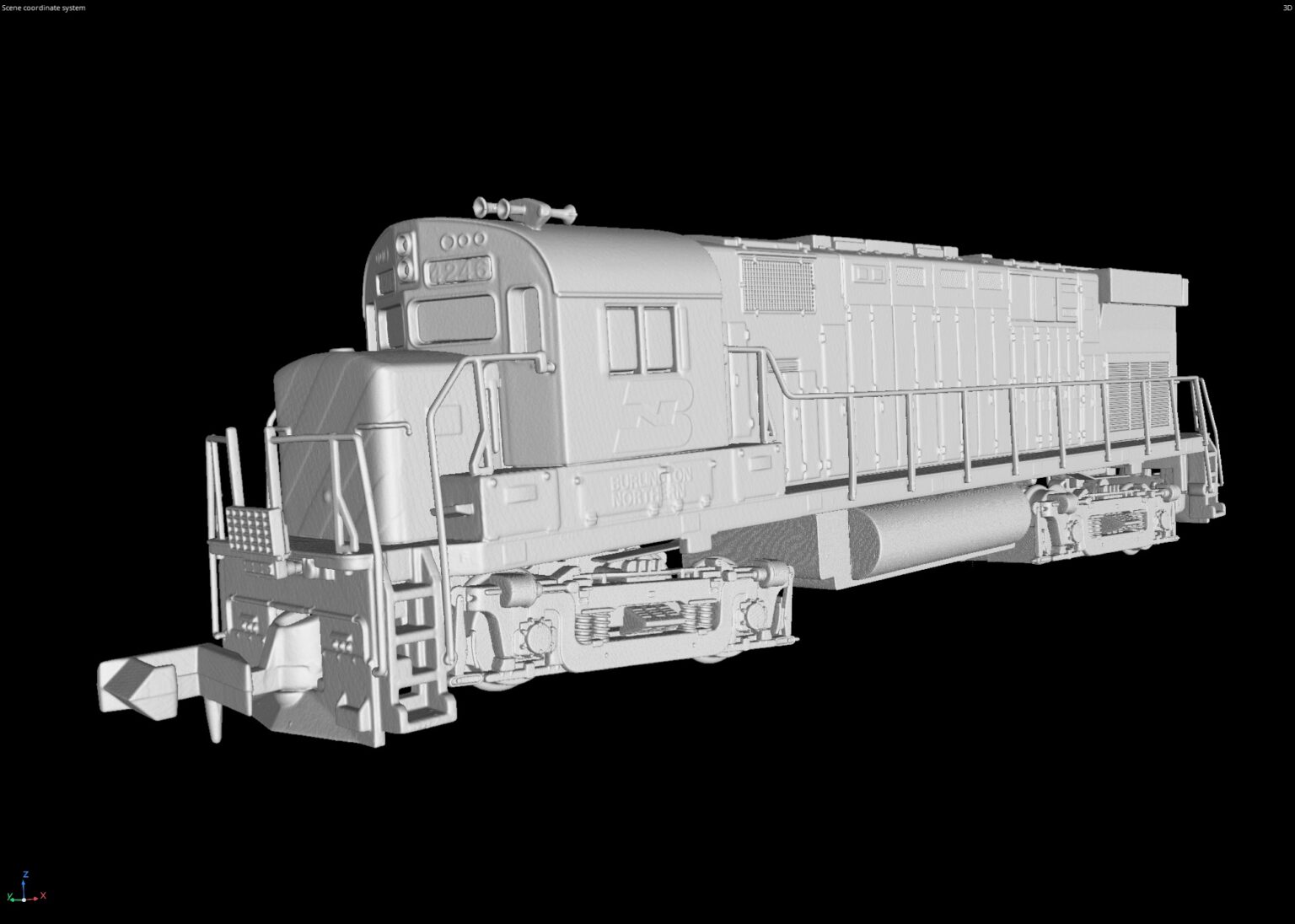

The Model Train in Question

Most of the trains I collect are from manufacturers that are no longer in business or were limited-run models. With this in mind, I must find new trains for my collection on places like eBay. Recently, I saw a particularly rare N-scale model of a locomotive called an ALCO C424, produced for just a few years in the early 2000s. When I found two for sale on eBay listed in good condition and running well, I snatched them up!

Most of the trains I collect are from manufacturers that are no longer in business or were limited-run models. With this in mind, I must find new trains for my collection on places like eBay. Recently, I saw a particularly rare N-scale model of a locomotive called an ALCO C424, produced for just a few years in the early 2000s. When I found two for sale on eBay listed in good condition and running well, I snatched them up!

Imagine my disappointment when I set one of them on my test track, turned on the power, and it moved a mere 3 inches before grinding to a halt. I immediately knew there was an issue with some part of the drive mechanism. It could be the motor, the worm gear, a short circuit, gear misalignment, or any of several issues. Where to begin? I could dismantle the locomotive and carefully examine each component, or I could CT scan it…

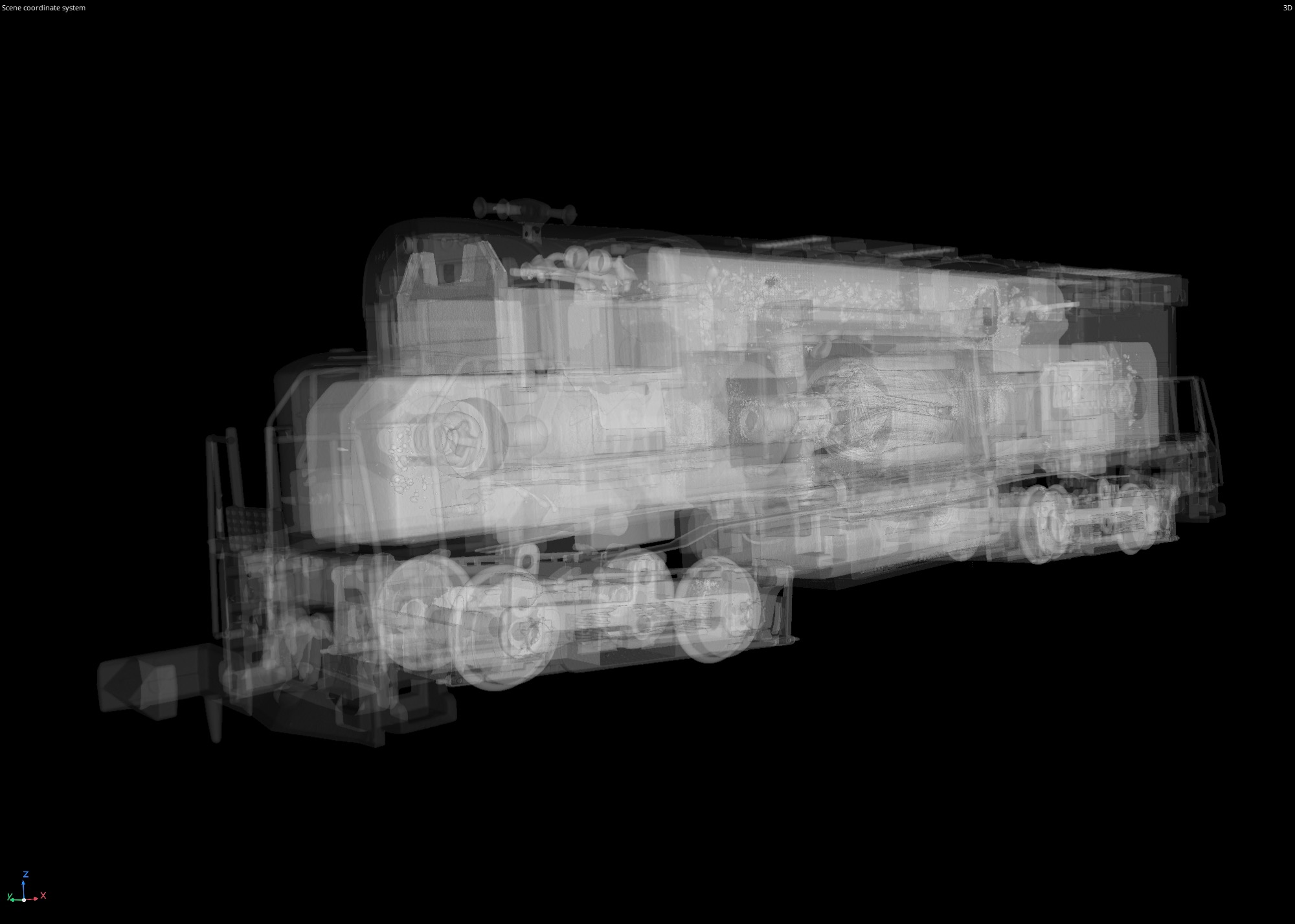

Using CT Scanning to See Inside

CT scanning was the perfect tool for this assignment. With the model’s small size, it could achieve high resolution and high magnification. Any significant disassembly was unnecessary because of the ability to scan multiple assemblies in a single scan.

CT scanning was the perfect tool for this assignment. With the model’s small size, it could achieve high resolution and high magnification. Any significant disassembly was unnecessary because of the ability to scan multiple assemblies in a single scan.

The materials involved in this locomotive are primarily plastics and low-density cast alloys.

- The shell is made of styrene to show detail, and the couplers and railings are Delrin plastic for durability and flexibility.

- The shell and motor alone are not heavy enough to maintain adequate electrical contact with the rails, so extra weight is added to the chassis.

- That weight comes from a metal split-frame made of a Zinc/Tin alloy.

- The densest components in this scan were the motor, screws, and any steel alignment pins.

However, due to the majority of materials present being low density, image artifacts were limited.

A 3D CT Scanning Success Story

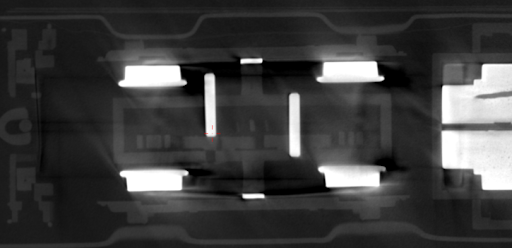

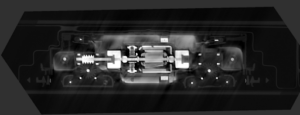

Our 3D CT Scanner gave me exactly the information I needed. On one model, I found that a single greased alignment pin for one of the wheelset gears had partially slid out of the frame and caused the gears to seize. With this knowledge, I could quickly repair the train using a toothpick, patience, and a steady hand.

On the second model, scanning revealed that a worm gear was entirely missing. Meaning the model was running at only half of its power capability. After ordering a new worm gear, I was able to make the repairs, and now the model locomotive runs perfectly!

Using X-ray imaging to help diagnose these model train issues and aid in its repair was incredibly fun! As I expand my collection, I’ll continue using CT even more to measure internal components and compare them to blueprints or CAD files. I could also use CT to reverse engineer components from a model no longer in production. With this technology, the capabilities and benefits are almost endless.

Trust Avonix With Your Passions

So, what are you passionate about? Whether you’re building a new piece of equipment or scoping out potential mechanical setbacks, our multi-industry 3D imaging services can help you problem-solve efficiently.

Avonix Imaging’s X-ray imaging allows us to see inside components without dismantling, damaging, or disrupting them. Learn more about our innovative scanning solutions.

Systems Used:

Nikon XTH 225kV | Reflection Target | Varex 1621 Panel

3D CT Scanner: 60 um voxel size, 220 kV, 273 uA